How does a gas spring work

Today, gas springs are a common component of many devices. For example, they provide support for safe lifting, positioning, pulling, dropping, or compensating weights. Moreover, using modern bores allows controlled speeds and it is possible to achieve various damping properties through oil filling. Unlike traditional coil springs, gas strings are distinguished by a flat spring characteristic, which may be influenced by a variety of factors.

The main advantages of Bansbach Easylift gas springs:

- controlled speed;

- damping;

- maintenance free;

- easy mounting;

- flat spring characteristic;

- lockable.

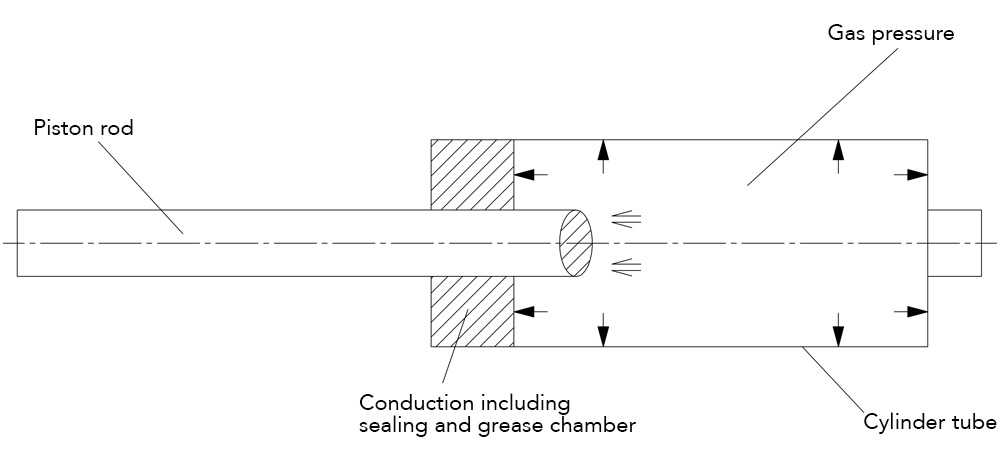

A gas spring is a sealed energy source and mainly consists of a piston rod, seals, and a pressurised cylinder (it therefore acts as a force accumulator). Nitrogen (N2) and oil are used for filling, while the physical properties are responsible for extending the piston rod. In closed environments, gases and liquids will spread in all directions under uniform pressure. Gas can be compressed, but oil can not (see figure 1.)

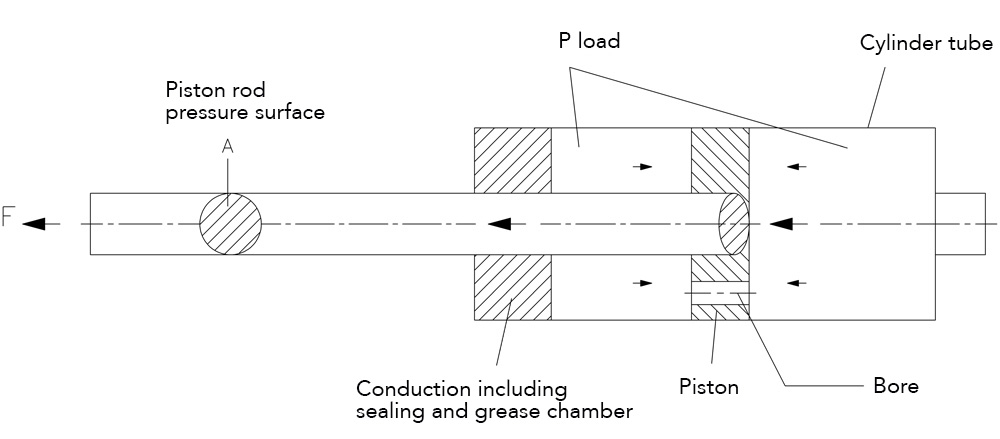

Compared to the outside atmosphere, the pressure in the sealed cylinder is overpressure. As can be seen in figure 2, the bore ensures equal pressure in both chambers. The piston rod area will continue to function as an effective working area, which is affected by the pressure in the gas spring.

Operation of lockable gas springs

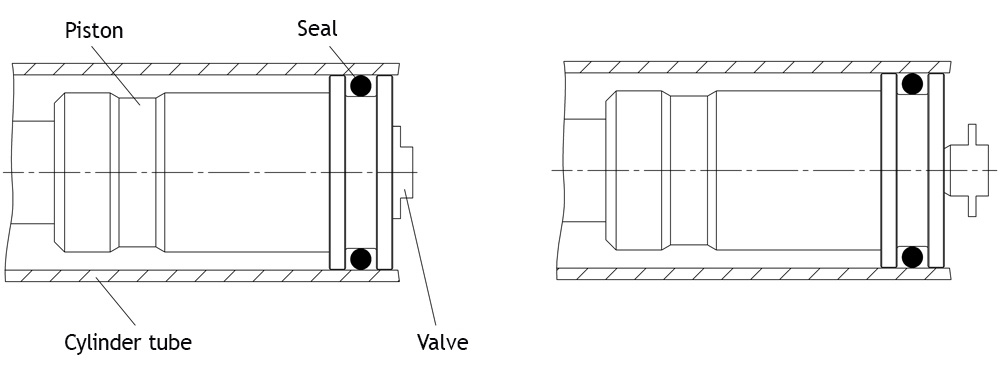

In contrast to regular gas springs, lockable gas springs can be locked in any desired position.

Typical applications include, for example, height adjustment of tables and back adjustment of beds or chairs.

Similar to regular gas springs, the extension force provides the counterweight. The valve (see figure 3) can be pushed out of the piston seat by pressing the release bar. As a result, the gas/oil can flow through the piston and the piston rod will extend or can be retracted with little effort. As soon as the pressure on the release rod (mechanism) is released, the valve will close as a result of internal pressure in the cylinder. The piston rod will lock in this position.

Because the piston is locked, additional holding force is generated under load.

This force, also referred to as locking force, depends on the type of lockable gas springs. There are four basic types:

- spring-loaded lock (B);

- rigid lock in extension direction (K);

- rigid lock in retraction direction (P);

- rigid lock in extension and retraction direction (KX).

By applying different piston techniques, many other variations are also possible. As is the case with regular gas springs, here too the length, force, speed, progression, and so on can be heavily customised.