Industrial presses

BIBUS is the official Benelux importer of German manufacturer Mäder's presses. Mäder is a manufacturer of a wide variety of modular, manually operated, and compressed air presses, including accessories.

This includes presses ranging from toggle presses, rack and pinion presses, pneumatic presses to hydropneumatic presses, available in hundreds of different versions. Mäder presses are extremely versatile and can be used for assembly, pressing, joining, bending, crimping, riveting, punching, gluing, and much more.

The force range of the presses varies from 30 N (a pneumatic press) to 100 kN (hydropneumatic press). Our presses are characterised by a high degree of flexibility, excellent quality, modularity, and fast delivery times.

Each model from the Mäder range is equipped with an accurate guided ram for realising low-friction, precise movements. In addition to accessories, the presses can be expanded with a two-hand control, foot control, and/or process monitoring by means of force/path diagrams. All aforementioned models are available as a standard version or according to customer specifications, such as greater working heights and deeper offsets.

If you have any questions or if you are looking for personal advice, please feel free to contact us.

Toggle presses

BIBUS offers a complete range of toggle presses for various industrial applications, including presses with a round or square ram. The toggle presses are extremely suited for production processes and series processing where no automation is required. The presses can be used quickly and flexibly.

Because these hand presses have a high degree of load capacity and accuracy, they are ideally suited for applications where power and reproducibility are required. Moreover, thanks to the high pressing accuracy, the equipment is play and maintenance free.

These hand presses allow for simple, accurate, and quick execution of a variety of processes. Below are several examples:

- assembly;

- pressing;

- bending;

- riveting;

- cutting;

- punching;

- shaping.

Why Mäder toggle presses

Flexibility:

complete range, wide selection of accessories, fully customisable.

Quality:

accurate guiding ram, low-friction movement, robust construction, cast steel frame.

Other accessories:

fine adjustment, table bore, stroke counter, return stroke lock, tools.

Benefits:

best value for money, possibility to add accessories afterwards, twelve months warranty, fast delivery.

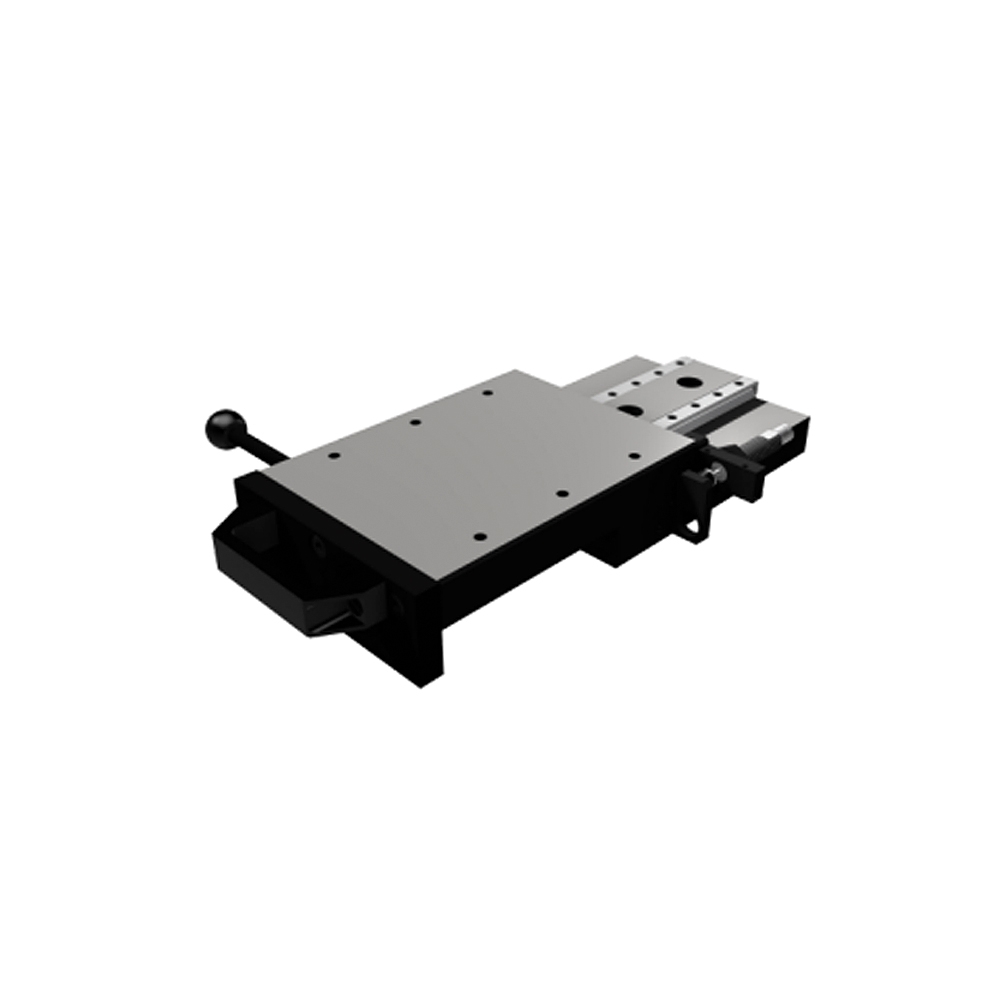

Rack and pinion presses

BIBUS offers a wide range of rack and pinion presses, including presses with a round or square ram. The rack and pinion presses are extremely suited for production processes and series processing where no automation is required. The presses can be used quickly and flexibly.

Because these hand presses have a high degree of load capacity and accuracy, they are ideally suited for applications where power and reproducibility are required. Moreover, thanks to the high pressing accuracy, the equipment is play and maintenance free.

These hand presses allow for simple, accurate, and quick execution of a variety of processes. Below are several examples:

- assembly;

- pressing;

- bending;

- riveting;

- cutting;

- punching;

- shaping.

Why Mäder rack and pinion presses

Flexibility:

complete range, wide selection of accessories, fully customisable.

Quality:

accurate guiding ram, low-friction movement, robust construction, cast steel frame.

Other accessories:

fine adjustment, table bore, stroke counter, return stroke lock, tools.

Benefits:

best value for money, possibility to add accessories afterwards, twelve months warranty, fast delivery.

Impact presses

Ideal for punching small quantities or riveting.

Controlling this press is very simple: as soon as the ram reaches the workpiece with its clamped tool, the spring is tensioned by a manual force on the manual grip. At the end of the spring-loaded stroke, the built-up force is abruptly transferred to the workpiece. The impact of the stroke can be set to unlimited by means of the star button.

Ready for use pneumatic presses

DA presses are ready for use pneumatic presses equipped with modern press technology. Thanks to their modular design, we can supply the presses entirely in line with your wishes, all at the best value for money. Standard stroke lengths of 40 mm to 120 mm can be ordered in steps of 20 mm. Special lengths can in most cases be produced upon request.

Ready for use pneumatic presses produce a constant force across the entire stroke length. All ready for use pneumatic presses can be equipped with automation or manual features.

In addition, the presses are also highly suitable for the processing of sheet metal, printed circuit boards, and other large parts. Although this processing often requires a deeper neck, the XL-DA presses with 250 mm and 300 mm deep necks should provide the perfect solution.

L-DA presses have a maximum distance of 350 mm between the ram and foot, allowing for the processing of workpieces that require more vertical space. Looking for a different sized press than our standard sizes? No problem! Presses with a welded frame can be fully customised based on your specifications.

Because all components are mounted in bearings, all ready for use pneumatic presses are more or less maintenance-free. The cylinders are lubricated and therefore suitable for oil-free operation.

Quality characteristics:

- hard chromed ram guide with Teflon buses;

- Easy height adjustment of the press head;

- Fast reproduction of settings when the tool is changed;

- Virtually maintenance-free double-acting cylinder;

- adjustable cylinder for end-position damping;

- low noise level: less than 75 dB.

DAP portal presses

The DAP portal press consists of standard Mäder components: DAF press cylinder and portal frame with ram plate The cylinder in use generates constant force throughout the entire stroke. Mäder DAP portal presses are available as automation components or with Mäder controllers MPS-1 and the TPC-MIDI process monitor.

Quality characteristics:

- forces ranging from 4.5 kN to 34 kN;

- stable construction;

- anti-twist lock and guided ram plate with two columns;

- ram plate allows for flat pressing;

- cross shaped slots for safe accommodation of tools;

- plenty of room for moulds;

- distance between ram and foot can be occupied by a filling canister;

- on request: the portal press can be supplied in different sizes.

DAF press cylinders

DAF press cylinders with flange are designed for flexible use in custom machines. DAF press cylinders are easy to integrate and come with all the advantages of modern pneumatic presses:

- stepless adjustment of stroke length;

- adjustable position end cushioning;

- mounting hole for tools;

- easy to automate.

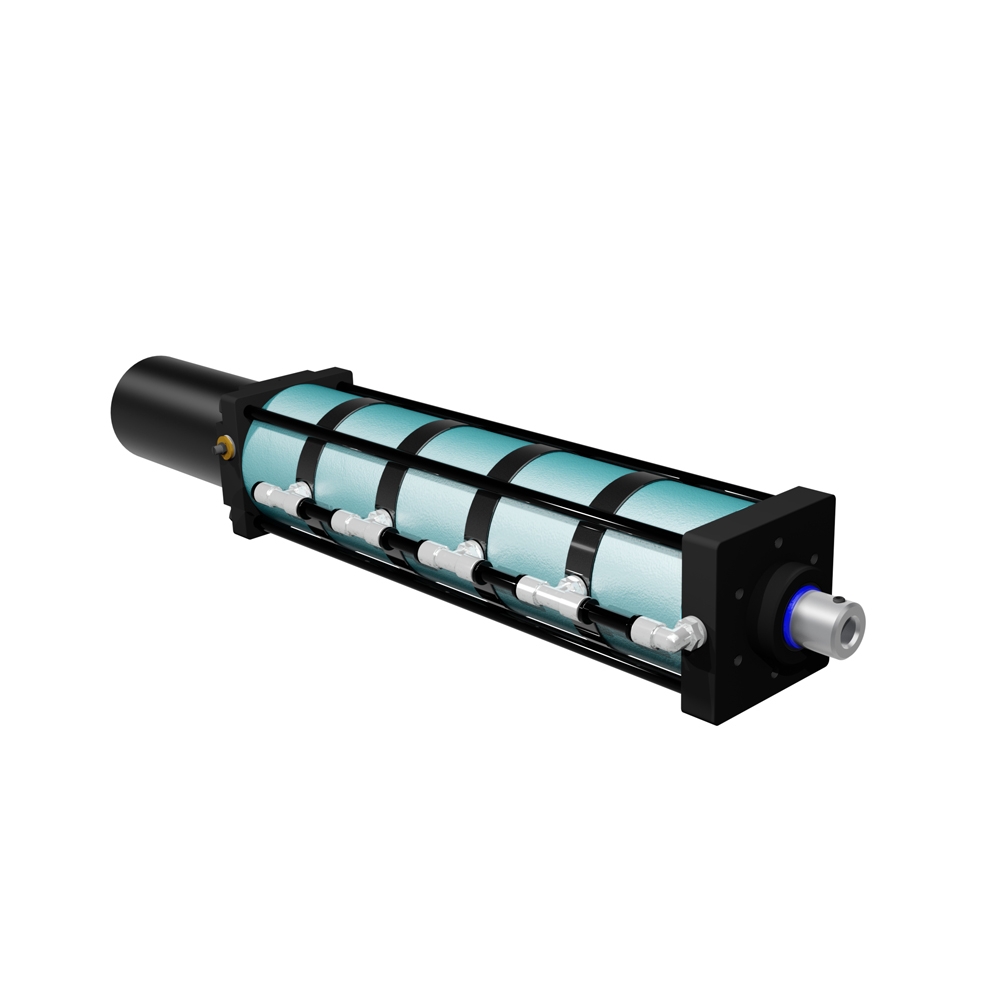

Hydropneumatic presses

Hydropneumatic presses are originally driven by compressed air and automatically activate the hydraulic stroke. This way the advantages of pneumatic and hydraulic presses are combined. In the pneumatically driven stroke, the workpiece is processed with a low force. The hydraulic stroke automatically actives in the event of resistance.

As a result, energy is consumed in the most economically effective way. Because the press does not require a hydraulic power converter, the press can also be used in smaller workplaces. All hydropneumatic presses can be supplied with a standard Mäder or custom controller.

Processing of sheet metal, printed circuit boards, and other large components requires a large press neck. Fortunately, XL-DA presses with neck sizes of 300 mm offer a solution. Looking for a different size press or one with a soldered design? We can tailor our presses entirely to your wishes!

Quality characteristics:

- anti-twist, hardened arm;

- long, ground ram guide for maximum precision;

- standard of two stroke lengths;

- easy height adjustment of press by means of screw and right-angle gear;

- side-mounted measuring strip for quick display of settings when the device is being replaced;

- low noise level: less than 75 dB.