High speed valves

MATRIX high-speed valves

MATRIX Technology

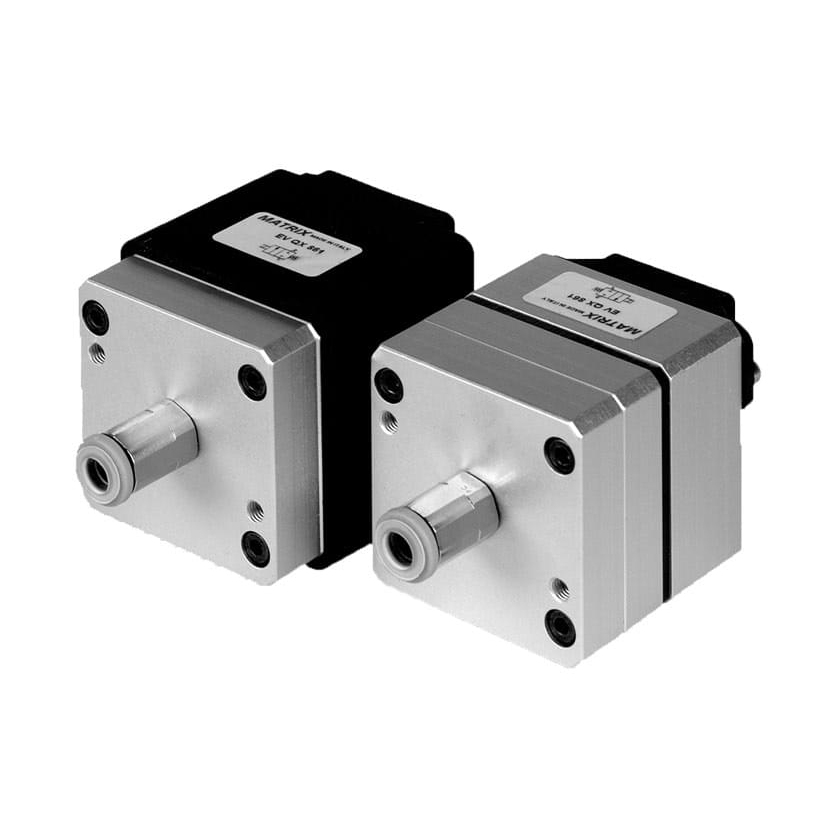

Zero Internal Friction

Traditional solenoid valve technology is prone to various reliability and performance problems due to its design, component inertia, high temperatures due to the large electrical coils, and especially due to internal friction of the components.

The MATRIX technology uses two highly innovative principles;

- the absence of internal friction during the opening and closing of the valve (ZIF - Zero Internal Friction technology);

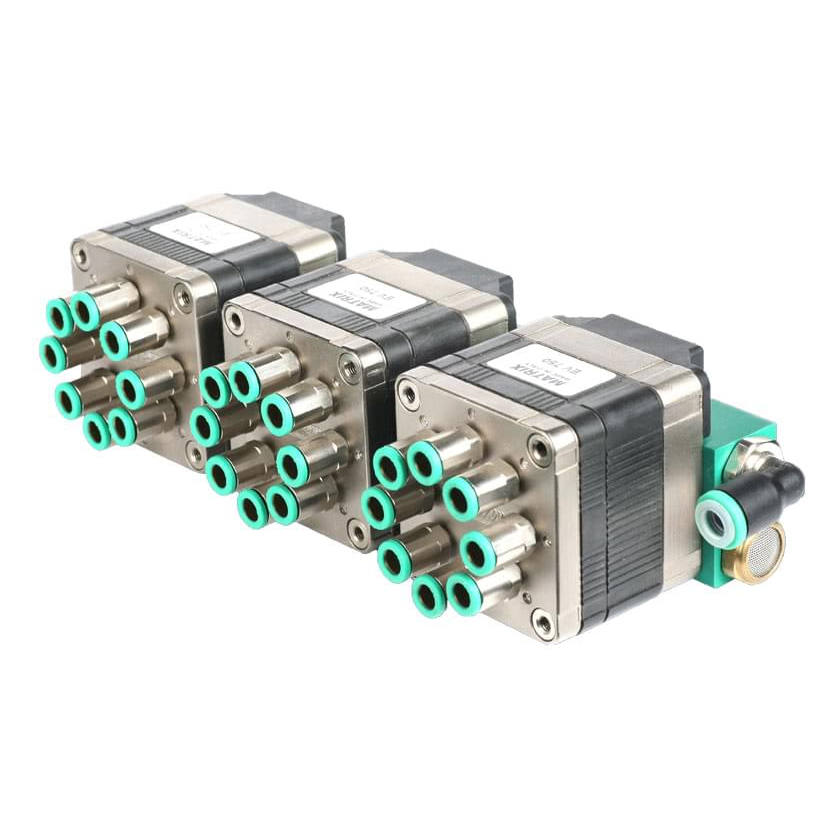

- the modular architecture that allows multiple valves to be mounted in a single body for extreme performance and flexible configurations.

MATRIX valves, based on the proven and patented Zero Internal Friction (ZIF) technology, with lightweight components and energy-efficient materials, offer outstanding performance in terms of response time, reliability and durability, ensuring extremely fast activation, precision and high repeatability. (see fig.1)

Speed-Up technologie

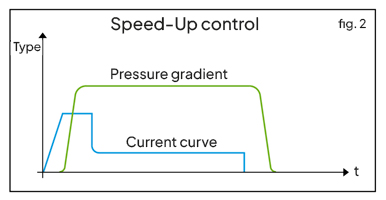

To reduce the energy consumption of the valves, MATRIX uses Speed-Up technology (also known as Peak & Hold) (see fig.2). This means that the valve only requires 100% power from the control system merely in the opening phase and this is then reduced to a holding level after < 5 ms. This saves > 90 % of the energy costs and at the same time reduces heat generation.

Flow control techniques

Pneumatic solenoid valves can be divided into two categories: digital on-off and proportional. Digital solenoid valves combine their open/closed position with an electrical on/off control, while proportional solenoid valves combine a particular position with a tension or variable current control device. MATRIX valves can be controlled directly (on/off signal) with the modulations listed below.

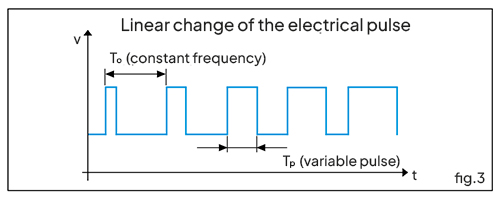

PWM / Pulse-Width-Modulation (fig. 3): is the generation of a square wave at constant frequency with variable pulse duration. A linear increase of the duty cycle rate corresponds to a linear increase of the pulse duration, which means a proportional variation of the flow (2/2 NC). The flow can take infinite values between 0 and the maximum flow related to the valve’s characteristics.

PFM / Pulse-Frequency-Modulation (fig. 4): is the generation of a square wave with variable frequency (period) and constant pulse duration. FPM control of a 2/2 NC solenoid valve means that the maximum flow through the valve varies in proportion to the frequency.

PNM / Pulse-Number-Modulation (fig. 5): is based on the characteristics of the multi-shutter valves and is the generation of on-off control groups. This means that a PNM control (variable from 0 to n) applied to a n shutter group of equal flow, implies a proportional variation to n of the passing flow. The flow rate can take n values depending on the number of shutters controlled.

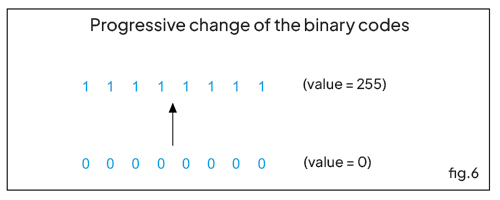

PCM / Pulse-Code-Modulation (fig. 6): is based on the features of the 860 series multi-shutter valves and takes up the principles of binary coding, typical of computers, and consists of generating on-off control groups with shutters having different flow characteristics. This means that the flowrate can take on various values depending on the combination of shutters used. In the case of 8 shutters, there are 256 flow values between 0 and maximum flow.