Explosion proof devices (ATEX)

Order explosion-proof equipment (ATEX) through sales@bibus.nl or 0252-433733

Ordering explosion-proof equipment (ATEX) at BIBUS

In BIBUS' product range, you will find a complete range of explosion-proof devices (ATEX) for level and temperature measurement. Use one of the forms below to get a first impression of the type of product you are looking for and how we can support you. Once completed, send the document to sales@bibus.nl. We will try to process your request as soon as possible. Need tailor-made advice? Then contact the specialists at BIBUS without obligation.

Exploring the ATEX Directive

The ATEX Directive isn't just a mere set of regulations; it's a comprehensive framework applicable throughout Europe. Its scope encompasses conformity assessments, product marking, technical documentation requisites, and more. This directive is pivotal in various industries, playing a crucial role in ensuring occupational safety and security. By mitigating the risk of explosions and their aftermath, it establishes a secure work environment.

At its core, the ATEX directive exists to guarantee the safety of individuals, property, and the environment within potentially explosive atmospheres. These environments emerge when substances like gases, vapors, mists, or dusts mix with air, creating conditions ripe for explosion.

The ATEX directive spans across diverse sectors where explosion hazards are a potential threat, including but not limited to the chemical, oil and gas, pharmaceutical, food, and mining industries.

Key ATEX Directive Considerations

The directive emphasizes that equipment and protective systems deployed in potentially explosive atmospheres must meet specific criteria to operate safely and dependably. Compliance with the ATEX Directive is not merely a formality; it's a crucial aspect of maintaining safety standards. Equipment falling short of compliance poses substantial risks to human safety and the environment.

Guidelines for Safety

Ensuring safety in environments prone to explosions necessitates taking proactive safety measures. Critical considerations include:

- hazardous area classification: The directive classifies different zones based on the likelihood of an explosive atmosphere. Zones 0, 1, 2 pertain to gas atmospheres, while Zones 20, 21, 22 cover dust atmospheres;

- Conformity assessment: Manufacturers must subject their equipment and protective systems to conformity assessments, involving testing and certification by authorized bodies;

- marking: ATEX-certified equipment bears a distinct marking that communicates zone classification and other pertinent details;

- documentation: Manufacturers must furnish comprehensive technical documentation containing essential information about the product, its characteristics, conformity assessment, and more.

ATEX-Certified Product Examples

For companies operating in such environments, understanding the ATEX directive is paramount. Implementing safety measures involves selecting ATEX-certified equipment, regular maintenance and inspections, and providing employees with training on specific risks and precautions. Prioritizing safety not only adheres to regulations but safeguards lives and the environment in explosive-prone settings.

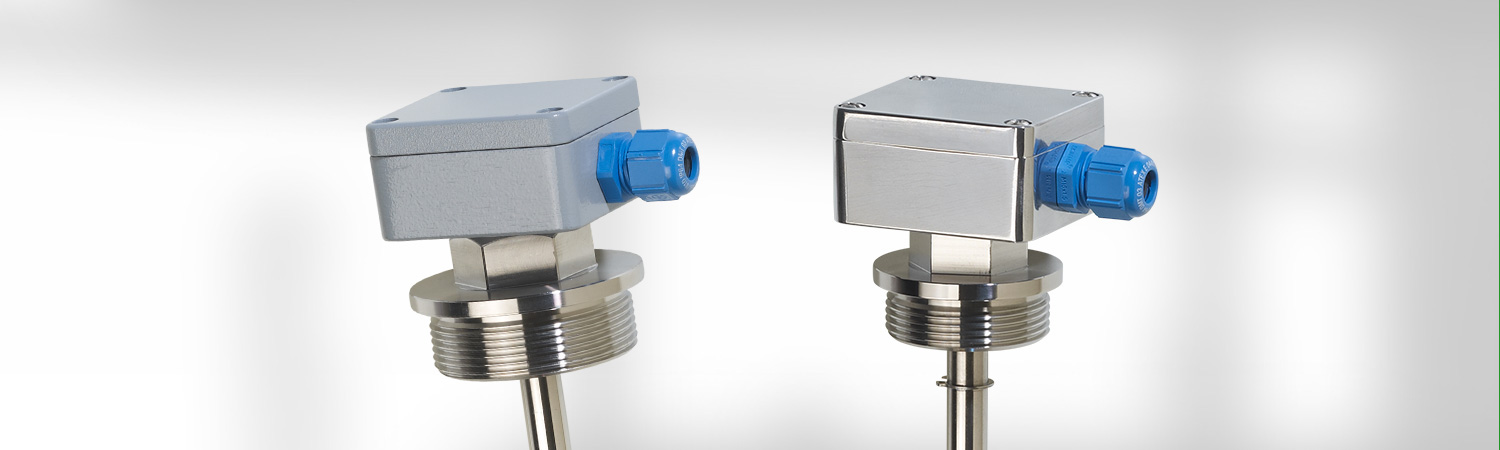

Numerous ATEX-certified products cater to potentially explosive atmospheres, including ATEX level switches, ATEX mini level switches, and ATEX temperature switches. These specialized products ensure safe operation in explosive environments, mitigating potential risks.

We would be pleased to receive the details of your application/situation in order to advise you on the possibilities of Engler temperature and level switches.