Gas springs

Gas springs can be ordered via sales@bibus.nl or +31 (0)252-433733.

Our range of gas springs includes a variety of dimensions and forces. Bansbach gas springs are used in almost every industry for numerous applications. From gas springs in machine and equipment construction to applications in the automotive and furniture industry. In addition, the gas springs are of a very high quality and even meet the requirements for the medical and aviation industry. View the options below.

| A1 | A1 | - | 4 |

|---|---|---|---|

| Connecting parts piston rod |

Connecting parts cylinder |

Model | Push-out speed / damping |

| See connecting parts | See connecting parts | -standard | 0 fast, no end damping |

| A: according to your drawing | 1 fast, normal end damping | ||

| B: according to our drawing | 2 fast, increased end damping | ||

| C: with scraper | 3 normal, no end damping | ||

| D: with covertube (-40°C to +60°C ) | 4 normal, normal end damping | ||

| E: with neutral labels | 5 normal, increased end damping | ||

| F: with valve inside the cylinder | 6 slow, no end damping | ||

| H: with special seals for temperatures up to 200°C | 7 slow, normal end damping | ||

| I: Stainless steel, AISI Nr. 304 | 8 slow, increased end damping | ||

| N: Stainless steel, AISI Nr 316L | 9 other variations | ||

|

|

R: with increased friction (F1 min: 6/15=100N, 6/22=100N, 8/19=120N, 8/28=120N, 10/22=150N, 14/28=200N) |

To recognize end damping please install with piston rod downwards |

|

|

|

S: with lockable cover tube (thread M8, above 150 mm stroke, up to 160°C) |

||

| T: with floating piston |

| 0 | 200 | 483 | 001* | 550N | |

|---|---|---|---|---|---|

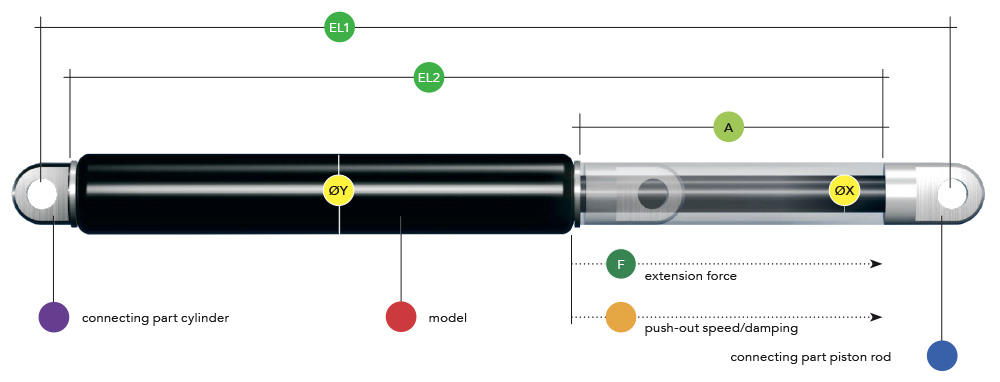

| Diameter piston rod / cylinder | Stroke | Extended length ** | Index No. | Extension force | |

| ØX/Øy mm | A (mm) | min. EL2 (mm) | F1 (N) | Progressivity approx. % | |

| K = 3/8 P = 3/10 G = 4/12 6 = 6/15 C=6/19 D = 6/22 0 = 8/19 1 = 8/22 E = 8/28 E = 8/28 2 = 10/22 3 = 10/29 4 = 12/28 5 = 14/28 N = 16/28 A = 10/40 F = 12/40 B = 14/40 7 = 20/40 R = 22/40 M = 30/70 |

10-120 10-120 10-150 10-150 10-150 10-150 10-300 10-300 10-300 20-800 20-800 20-1000 20-1000 20-1000 20-1000 20-1000 20-1000 20-1000 20-1000 100-800 |

2x Stroke +20 2x Stroke +32 2x Stroke +30 2x Stroke +30 2x Stroke +42 2x Stroke +43 2x Stroke +48 2x Stroke +48 2x Stroke +60 2x Stroke +47 2x Stroke +60 2x Stroke +60 2x Stroke +60 2x Stroke +60 2x Stroke +70 2x Stroke +70 2x Stroke +70 2x Stroke +90 2x Stroke +90 2x Stroke +120 |

*only necessary for repeating orders | 7-110 7-110 7-200 10-400 10-400 10-400 30-700 30-700 30-700 50-1300 50-1300 100-1700 150-2600 200-3200 50-1300 100-1700 150-2600 200-5000 300-6000 1000-12000 |

28% 20% 21% 27% 16% 11% 33% 22% 13% 39% 21% 33% 52% 85% 8% 13% 18% 45% 60% 25% |

** the total length is measured when the gas spring is set to the 'off' position, including mounting parts

Lockable gas springs

In addition to the standard gas springs, our range also includes lockable gas springs. Lockable gas springs are used in situations where applications can be set/locked in different positions with the gas springs.

Mounting parts

To ensure optimum operation of the gas spring, it is also important to choose the right mounting parts. We offer an extensive range of mounting parts for a detailed and controlled operation in your application, including eyes, yokes, ball joints, and metal brackets which are compatible with almost all gas springs. It is also possible to order mounting parts in steel and stainless steel. View the mounting parts

Options

Below are various products you can order with your gas springs.

| Size øx/øy | scraper EL2 + 10mm | cover tube EL2 + 10mm | cover tube alu EL2 + 3mm (ø40 + 5mm) | valve* | high-temp. seals | low-temp. seals | stainless steel | friction EL2 + 10mm | lockable cover tube EL2 + 26mm (slag min 150mm) | floating piston |

|---|---|---|---|---|---|---|---|---|---|---|

| 3/8 | ||||||||||

| 3/10 | ● | |||||||||

| 4/12 | ● | |||||||||

| 6/15 | ● (EL2 + 5mm) | ● | ● + 2mm | ● | ● | ● | ● | ● | ||

| 6/19 | ● | plastic | ● | ● | ● | ● | ● | |||

| 6/22 | ● | plastic | ● | ● | ● | ● | ● | ● | ||

| 8/19 | ● | plastic + steel | ● | ● | ● | ● | ● | ● | ● | |

| 8/22 | ● | plastic | ● | ● | ● | ● | ● | ● | ||

| 8/28 | ● | plastic | ● | ● | ● | ● | ● | ● | ||

| 10/22 | ● | plastic | ● | ● | ● | ● | ● | ● | ● | ● |

| 10/28 | ● | plastic | ● | ● | ● | ● | ● | ● | ● | ● |

| 12/28 | ● | plastic | ● | ● | ● | ● | ● | ● | ● | |

| 14/28 | ● | plastic | ● | ● | ● | ● | ● | ● | ● | ● |

| 16/28 | ● | plastic | ● | ● | ● | ● | ||||

| 10/40 | ● | steel | ● | ● | ● | ● | ● | ● | ||

| 12/40 | ● | steel | ● | ● | ● | ● | ● | |||

| 14/40 | ● | steel | ● | ● | ● | ● | ● | ● | ||

| 20/40 | ● | ● | ● | ● | ● | ● | ● | |||

| 22/40 | ● | ● | ● | |||||||

| 30/70 | standard | standard | ● |

* If you choose a gas spring with valve and hinge eyes, you have to take a screwable hinge eye for the cylinder side (see connecting parts)

Why BIBUS gas springs?

- custom gas springs;

- available in steel and stainless steel (304 and 316L);

- high quality and impressive service life;

- certified gas springs;

- installation in any desired position;

- on request, the gas springs can be supplied with Food Grade Oil (FDA);

- custom advice from our specialists.

Configuring gas springs

Our gas spring configurator allows you to easily determine the properties of your custom gas spring. The configurator allows for a great amount of flexibility: these gas springs are available in every size, force, and specification. Easily assemble your very own gas spring step by step.

Configure your gas spring directly >>

Get advice on your gas springs

BIBUS advises customers not to purchase standard gas springs, but instead to make sure the purchased springs are in line with their specific wishes and needs. Would you like to know more? Feel free to contact our gas spring specialists.