In various industries, pneumatic air treatment is essential to ensure that the compressed air is bacteria-free, dry and free of oil particles. This article focuses on CKD's Food Process compressed air conditioning (FP* Series). Read on to learn more about the distinctive power of reliable antibacterial and bacteria-removing filters of CKD's innovative modular design.

Food Process compressed air conditioning

CKD's Food Process compressed air conditioning offers an effective solution with three essential components: an antibacterial pre-filter, a high-performance antibacterial filter, and a bacteria-removing filter with a hollow fibre membrane.

Operation of compressed air conditioning: the modular design in action

The various filters are available in both single and modular types. This allows a combination to be selected based on the purity required for specific applications. In this way, BIBUS can always provide you with the right solution for your application. The different components of the filters are described below.

Step 1: the Antibacterial pre-filter

When the compressed air enters the Food Process system, it first passes through the anti-bacterial pre-filter. This first crucial step ensures that potentially harmful bacteria are intercepted before the air flows any further.

Step 2: High-performance antibacterial filter

The second component of the Food Process system is the high-performance antibacterial filter element. Here, a non-woven fabric containing antibacterial silver ions is used. These silver ions infiltrate bacterial cells, inhibit the action of bacterial enzymes and cause the elimination of bacteria.

Step 3: Bacteria-removing filter with hollow fibre membrane

The third and final component is the bacteria-removing filter with a hollow fibre membrane. This filter is composed of a straw-shaped fibre membrane with numerous special slit-shaped ultrafine pores. These pores act as a safety net for bacteria, removing 99.999999% of bacteria as the compressed air passes.

Certified and easy to maintain

CKD's Food Process compressed air conditioning has FDA approval, an LRV8 mark or higher and is fully compatible with the Food Sanitation Act. These certifications ensure the highest standards of quality and safety.

In addition, the series is not only certified, but also extremely user-friendly. Module parts can be easily replaced, and a convenient maintenance seal on the side of the Food Process indicates when it is time to change the filter.

Configure the right compressed air conditioning for your application

The table below lists various components of the Food Process range. The individual components offer the flexibility to put together the right compressed air conditioning for your application. Choose the combination that meets your specific purity requirements.

| Anti-bacterial/bacteria removal combination | Anti-bacterial combination |

anti-bacterial pre-filter |

Anti-bacterial High-performance filter |

Bacteria removing single filter |

Bacteria removing inline filter | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SFC307 | SFC407 | SFC306/SFC406 | SFC806 | SFC310/SFC410 | SFC810 | SFC320/SFC420 | SFC820 | SFC330 | SFC430 | SFS10 | ||

| Flow rate Unit: L/min (ANR) Primary side pressure 0,7 MPa |

300 | 500 | 360 | 700 | 2200 | 360/700 | 2200 | 300 | 500 | 300 | ||

| Bacteria removing performance LRV8 or higher |

✓ | ✓ | X | X | X | X | X | X | ✓ | ✓ | ✓ | |

| Anti-bacterial performance Bactericidal acitivity value 3 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | X | X | X | |

| Materials compatible with the Food Sanitation Act No. 370 of Ministry of Health | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Lubricant for food equipment NSF H1 Grease |

✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | X | |

| Modular connection | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | X | |

Explanation of terminology from the table above

- Bactericidal activity: This value is an assessment of the extent to which the growth of adherent bacteria is suppressed.

- Bacterial capture performance: This indicates the bacteria capture performance of the filter using test bacteria as defined in JIS K 3835. This is expressed as a log reduction value (LRV).

- Materials compatible with Food Sanitation Act: the materials used are compatible with the decomposition test for food and food additive standards and criteria, based on Section 18 of the Food Sanitation Act, which is used in the regulations for utensils, containers and packaging for the liquid transit section.

- Materials compatible with FDA: Materials compatible with the dissolution tests of FDA (the U.S. Food and Drug Administration) regulation 21CFR part 175 (Adhesives and components of coatings) and part 177 (Polymers) are used in the liquid passage section.

Compressed air conditioning applied in various industries

There are several industries that benefit from clean, dry and oil-free compressed air. The examples below illustrate the versatility of hygienic compressed air conditioning in various industrial processes, where antibacterial and bacteria-removing filters play a crucial role in ensuring safety and quality.

1. Cooling cooked rice

1. Cooling cooked rice

After cooking, rice is quickly cooled using safe compressed air filtered with a bacteria-removing filter to prevent bacterial growth.

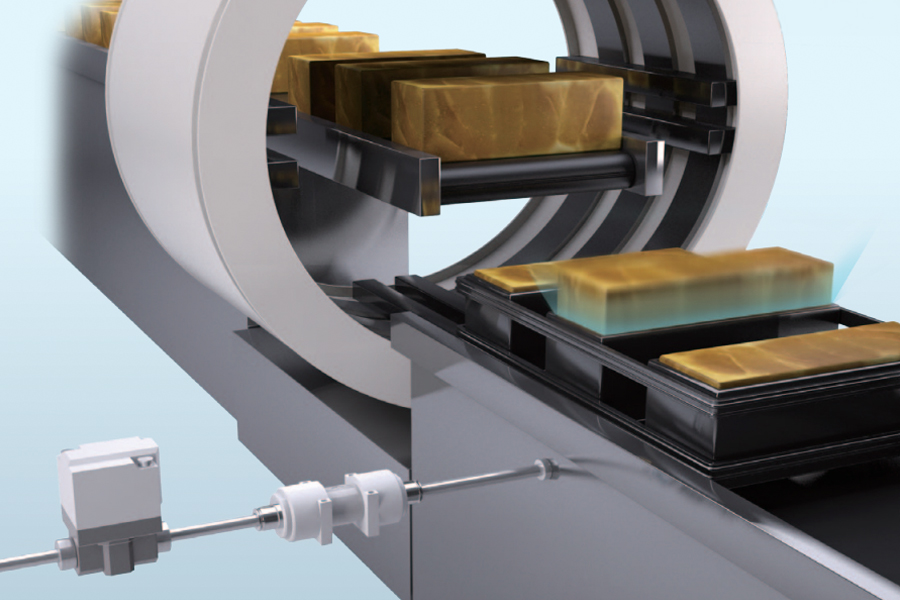

2. Bread processing

2. Bread processing

When removing freshly baked bread from the mould, safe compressed air with a bacteria-removing filter is introduced between the bread and the mould.

3. Mixing with added air

To give food a smooth texture, safe compressed air, filtered with an antibacterial/bacteria-removing filter, is mixed with the ingredients.

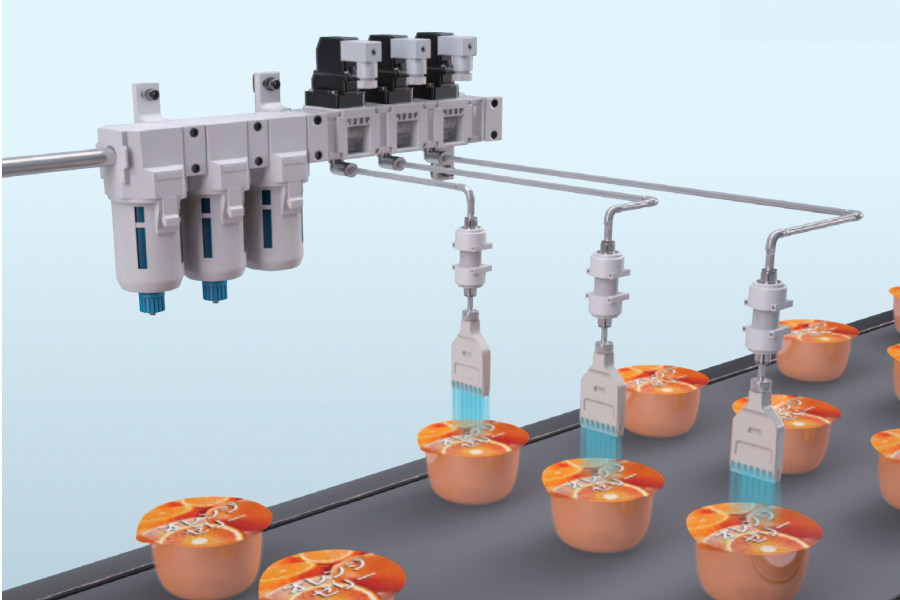

4. Spray coating of food

In the process of keeping dough moist and coated with oil, chocolate or soy sauce, food products are fluidly coated with compressed air filtered with an antibacterial/bacteria-removing filter.

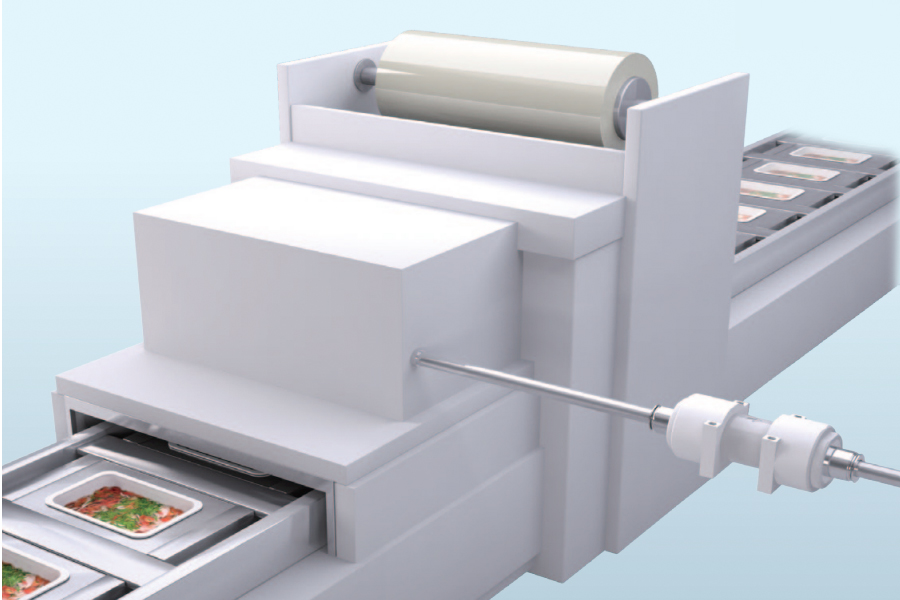

5. Nitrogen flushing in packaging machines

To prevent oxidation of food, packages are filled with safe nitrogen filtered with an antibacterial/bacteria-removing filter in the nitrogen flushing line.

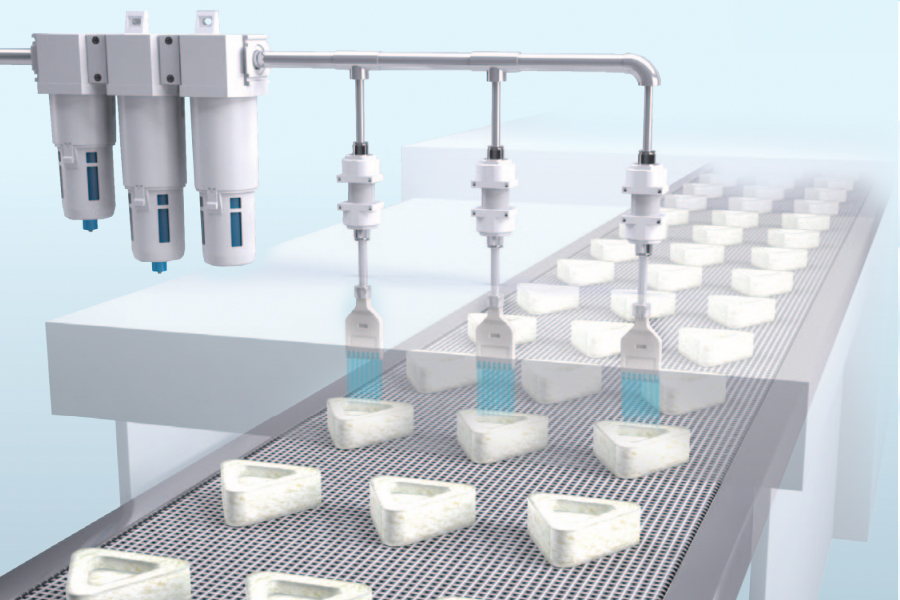

6. Cleaning food residues

Compressed air, filtered with an antibacterial/bacteria-removing filter, is used to remove food residues, water droplets and crumbs.

Tailored compressed air conditioning for your application

From reliable operation to certified maintenance, CKD's Food Process compressed air conditioning offers a comprehensive solution. Explore the full range and contact us for tailor-made advice.