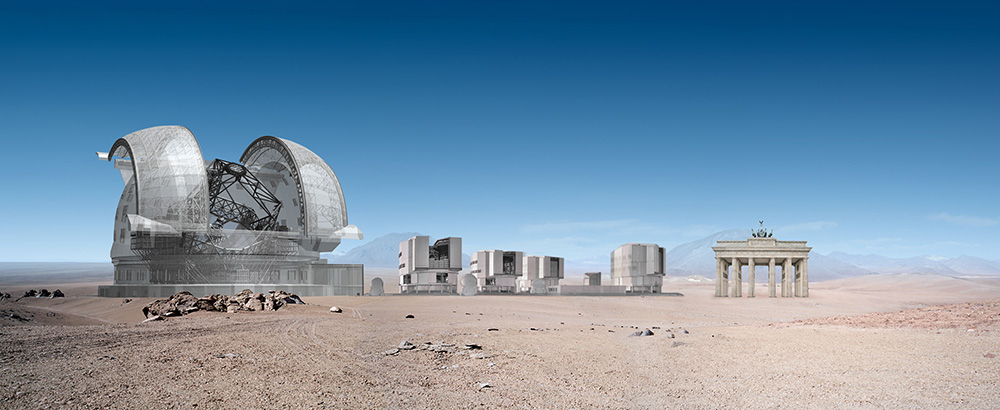

Photo Wikimedia Commons

There are few field applications that underline the diversity BIBUS’ product range as well as the world's largest telescope. In northern Chile, VDL ETG Projects and the European Southern Observatory are contributing to the manufacturing of the Extremely Large Telescope (ELT) at an altitude of more than 3 kilometers. BIBUS is proud of its role as supplier of VDL ETG Projects and this Dutch/European collaboration. This article elaborates on the ELT.

Extremely Large Telescope

Once finished, the ELT will rightfully be the largest telescope in the world. The design consists of a total of 798 supporting structures that together form the main mirror (the eye of the telescope). This mirror has a diameter of almost 40 meters. The scale of this prestige project only really becomes clear after a comparison with current technology and capacity in the field of astronomy. The ELT will able to collect more light than all large (professional) telescopes combined.

Photo Wikimedia Commons

Since it is not possible to manufacture a main mirror of this size in one piece, the decision was made to use nearly 800 hexagonal segments. The mirror segments are approximately 1.4 meters in size and 5 centimeters thick and are powered by electric motors.

An important aspect to achieve the high accuracy of the telescope is contained in the design of the mirror structure, in which precision actuators in combination with high-tech mechanical parts can be controlled. This structure is important in order to be able to adjust each mirror element individually very precisely to form a smooth whole.

The purpose of the telescope is built with the purpose of making scientific discoveries in the field of astronomy, such as the composition of nearby galaxies. The telescope is expected to be operational in 2024.

VDL Groep & ESO

This immense project is realized by the European Southern Observatory (ESO). VDL ETG Projects, part of VDL Groep, is working together with TNO and NOVA on the design and manufacture of the telescope. The cooperation and the overall construction of the telescope are managed by ESO.

VDL ETG Projects specialises in the development, production, assembly and worldwide installation of machines, devices, manufacturing equipment and hightech mechatronic systems and is located in Eindhoven.

BIBUS and VDL ETG Projects

As a supplier, BIBUS has the honor to contribute to this project. In collaboration with the partner of BIBUS, a ‘special’ has been developed; a smooth spring plunger without collar, with an h6 fit. Because this component is produced according to customer specifications, the spring plunger meets 100% the requirements of VDL ETG Projects.

Photo Wikimedia Commons

Spring plunger piece as machine element

BIBUS supplies a diverse range of machine elements. Besides gas springs, actuators, levelling feet, dampers, hinges and magnets, BIBUS also supplies customer-specific and standard spring plungers.

The spring plungers consist of a ball or a pin. In machine and equipment construction, the components are mainly used for positioning & securing, locking or decoupling. Spring plungers are relatively easy to remove, which means that the components are often used in applications where movable parts must be fixed quickly and easily. The Extremely Large Telescope is a good example of this.

In BIBUS’ range of spring plungers, you will find large variations in materials, dimensions and fixings. In addition to the standard models, BIBUS is also able to provide customer-specific spring plungers. Contact one of our specialists for tailor-made advice.