Working pressure and switching time are important process parameters within process engineering. Coaxial valves are valves known for fast switching times combined with high working pressures and are used to control the flow of liquids or gases. The valves are ideal for high viscosity media.

BIBUS has worked closely with Müller Co-ax GmbH for many years to share its knowledge of the coaxial valve. In this article, we discuss the operation of coaxial valves, the different types available and their advantages.

Operation of coaxial valves

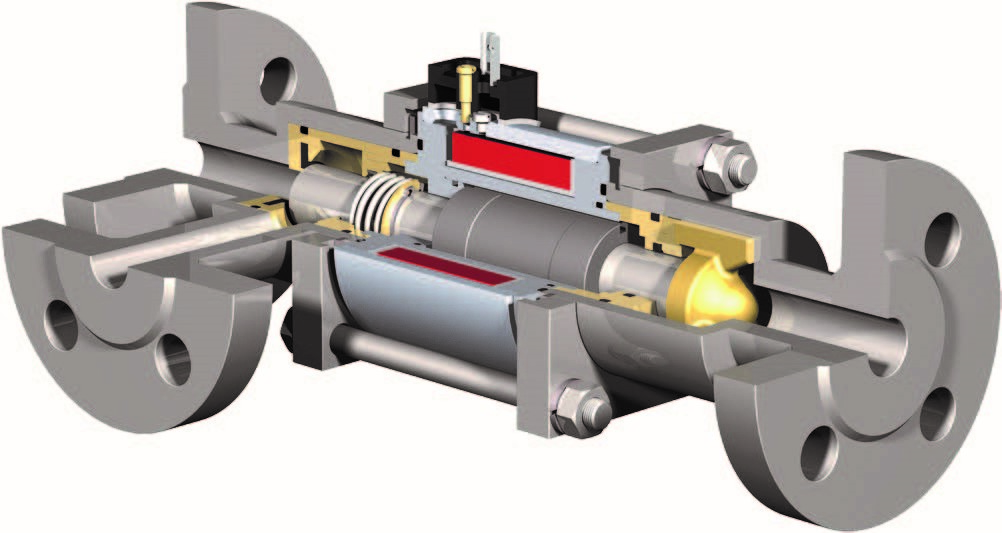

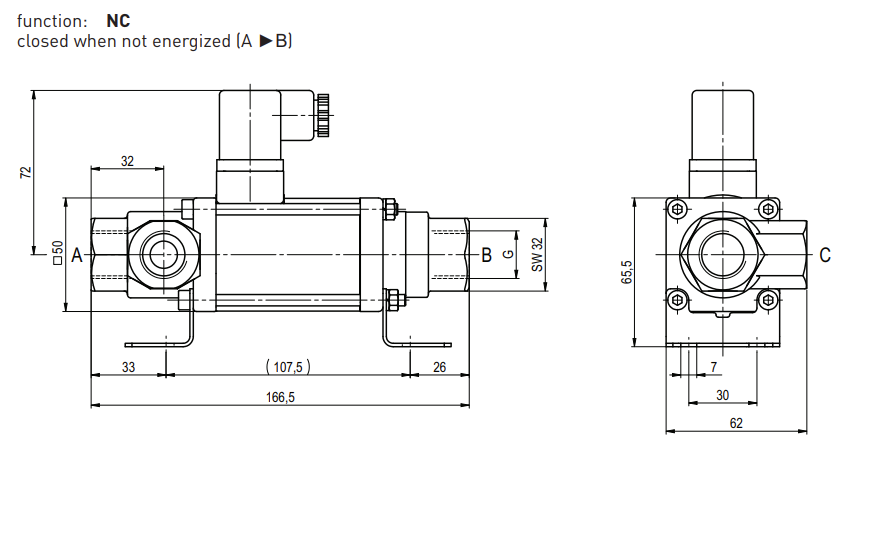

A coaxial valve works by means of a cylindrical tube that is laterally movable and can regulate or redirect the flow of the medium flowing through the valves. This lateral movement changes the position of the valve in open or closed position, regardless of the system pressure.

With a normally closed (NC) valve, it works as follows: when the coil is energized, the valve seat tube moves due to the pressure of a return spring. This allows fluid to flow through the valve. When the coil no longer receives power, the return spring pushes the tube back to the valve seat and closes the valve.

O-rings hold the coaxial tube in place, allowing lateral movement of the tube and preventing media from contacting other parts of the valve. With a normally open (NO) valve, it is exactly the other way around

Types of coaxial valves

There are several types of coaxial valves available, each with their own specific features and applications, tailored specifically for your application. Some of the most common types are, 2/2-way coaxial valves, the 3/2-way coaxial valves, also available in ATEX version.

-

2/2-way configuration the valve has 2 ports and can be supplied normally open (NO) or normally closed (NC).

-

A 3/2-way configuration can be used to change the direction of a fluid. In a normally closed (NC) configuration, the medium enters through port 1. When the valve is not energized the fluid moves from port 1 to port 3 and becomes the path to port 2 Once the coil is energized the valve seat will move causing the fluid to move from port 1 to port 2.

-

ATEX certified coaxial valves, Muller co-ax GmbH offers the possibility to apply the valves in situations where there is a risk of gas and dust explosion hazard. These ATEX certified valves are approved for ATEX Zone 1 Category 2, excluding mining. They are available in nominal widths from 10 to 50 mm and pressure ranges from vacuum to 500 bar medium pressure.

Application

Coaxial valves are well suited for the use of lubricants in machine and plant engineering. They also find their applications in vacuum and gas technology, test bench construction, marine and rail engines, and filling and dispensing technology. With suitable seals, they can be used in both gaseous and liquid, dirty or gelatinous media, such as oils, emulsions and coolants and lubricants.

Advantages

-

Coaxial valves offer several advantages over other types of valves. Here are some advantages of coaxial valves:

-

The coaxial design balances the force in the valve regardless of the system pressure.

-

The coaxial valves are available up to a working pressure of 500bar.

-

The unique design of the coaxial valve minimizes valve seat wear, even in extremely contaminated media. This makes the valves resistant to dirt.

-

The coaxial valves are energy efficient, meaning they consume less energy than comparable valves on the market. This can result in cost savings in the long run.

-

The pressure-balanced design ensures fast and repeatable operation.

-

The valve design allows the medium to flow in both directions.

-

Müller Coax valves have a compact design, making them easy to install in tight spaces. This is especially important in industrial applications where space is often limited.

Ordering coaxial valves

This article has discussed what coaxial valves are, how coaxial valves work, the types of coaxial valves and the applications of these valves. Would you like to learn more about the possibilities of coaxial valves in your industry? Then feel free to contact BIBUS now for more information and customized advice.