With the complete Wörner range of pallet stoppers, BIBUS is able to think with you to provide the perfect solution for all your assembly lines and transfer systems.

In the webshop, you will find, among other things, undamped and damped pallet stoppers, as well as angle dampers, index cylinders and shock absorbers - both pneumatically and electrically driven. This article will help you select the right pallet stopper for your application. Continue reading for a complete overview of the pallet stoppers or download the brochure for more information.

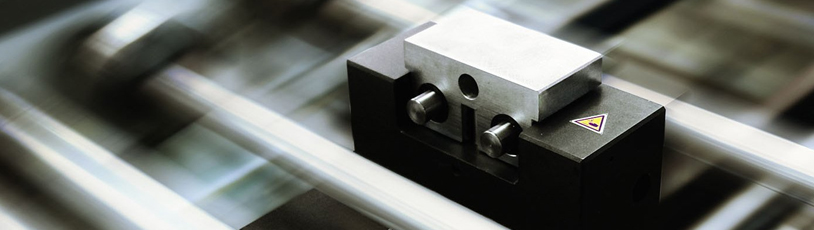

Stopper/Separating stops

Standard pallet stoppers are designed to accurately position one or more workpiece carriers at a stop point. Several models are available, including variants with an integrated damping system for a soft and vibration-free stop. Further transport of the workpiece carrier is possible after lowering the stop. Both pneumatic and electric actuating options are available.

Standard pallet stoppers are designed to accurately position one or more workpiece carriers at a stop point. Several models are available, including variants with an integrated damping system for a soft and vibration-free stop. Further transport of the workpiece carrier is possible after lowering the stop. Both pneumatic and electric actuating options are available.

Undamped Stoppers

Undamped stoppers are suitable for situations where one or more pallets must be accurately stopped. They increase productivity due to their short cycle times.

Damped Stoppers

For pallets with shock-sensitive or fragile items, the cushioned stoppers are ideal. Their infinitely adjustable damping mechanism gently decelerates the pallet, taking it to its final position smoothly, stably and vibration-free. These stoppers reduce the impact force by up to 95% compared to undamped variants.

Roller systems

Particularly slim design, for use in roller conveyor systems. No rollers need to be omitted to make room for the stopper.

Angle dampers

Angle dampers

Angle dampers are used for damping with a change of direction, especially for pallets on which there are shock-sensitive or fragile parts. An infinitely adjustable pneumatic damping mechanism gently stops the pallet upstream (transverse or traverse) and then guides it downstream (transverse or traverse).

Index cylinders

Index cylinders

Our index cylinders provide precise vertical lifting of pallets - making them ideal for fast positioning. The workpiece can be machined and/or assembled without being affected by vibration. Sensors can be used to detect the upper and lower position of the stop.

Anti-bounce stops

Anti-bounce stops

Pneumatically operated anti-bounce stoppers keep the pallet with workpiece in the required position. And thus prevent the workpiece from "bouncing" back. These modules are usually used in combination with undamped stoppers/separators and are recommended for low-friction transfer systems.

Acceleration units

Acceleration units

The acceleration unit accelerates the exit of the pallet from the process station, causing the next process cycle to start earlier. This can reduce cycle times by more than 40%. It is thus ideal for use in short-cycle transfer systems.

Displacement stops

Displacement stops

Wörner displacement stoppers are installed at places in the transfer system where the pallet can go in more than two directions. For example, crossings. The unit is mounted between these two parallel length sections. The displacement stoppers thus reliably take over transport control at line crossings. Thus, pallets can be transferred from a transverse to a longitudinal direction.

The right pallet stoppers for your application

Does your application have special requirements or does your project require a special solution? Feel free to contact one of our specialists for tailor-made advice. For more information, view the pallet stoppers brochure or visit the pallet stoppers page.