BIBUS is a one-stop-shop partner for the machine and equipment construction and other sectors. In order to provide the best possible service to different sectors, we constantly keep an eye out for mechanical solutions that can be innovative for customers.

An important pillar of Mpart's product range consists of fastening components. In this package you will find spacers, quick rivets, pressure joint solutions and recently also blind rivet nuts and blind rivets. In this way BIBUS can always offer the right solution for fastening issues.

This product group has been added because, among other things, the closures and hinges from the BIBUS range are often attached using blind rivets and/or blind rivet nuts. In this way BIBUS can offer the most complete solutions as a one-stop-shop. This article describes how blind rivet nuts work. The operation of the blind rivet was explained in an earlier article.

How a blind rivet nut works

Blind rivet nuts have a hollow/tubular front piece that makes it possible to fix a nut in a hole, without having to reach the back. Blind rivet nuts can be placed in a blind hole, just like blind rivets.

This means that only one side of the plate, tube, tube or other object needs to be accessible. For other fastening solutions, such as pressure joints (clinching), both sides of the workpiece must be accessible. Blind rivet nuts can therefore be used for a wide range of applications.

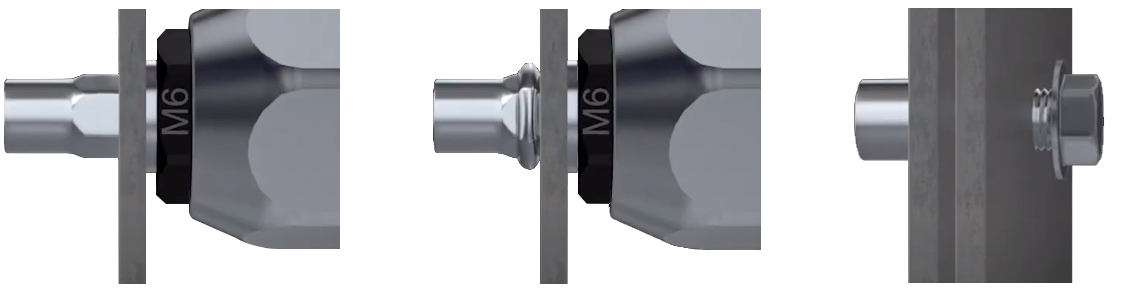

The blind rivet nut is spun onto a threaded pin and then placed in a suitable hole by means of a (pre-set) axial movement of the threaded pin. Due to the axial movement, the shank of the nut expands against the surrounding material and a thickening forms at the rear, this creates the mechanical fastening / locking. A blind rivet nut can be installed within seconds, with the right tools this can be done within 3 seconds! After the blind rivet nut has been placed, no post-processing is necessary.

After placing the blind rivet nut, the workpiece is provided with an internal screw thread, which is also much stronger, especially with thin or less strong materials. The applied thread can then be used to connect another object with a bolt or screw. The major advantage of blind rivet nuts compared to blind rivets is that the connected product can be disassembled and can therefore be easily disconnected at any time.

An example of installing a blind rivet nut can be seen in the video below:

The benefits of a blind rivet nut

Due to the simple, fast and strong connection and the wide range of different designs, blind rivet nuts are used in a large number of industries and applications. This includes, for example, the automotive industry, HVAC, machine and equipment construction, aerospace, food equipment and metal production.

The advantages of blind rivet nuts are:

- Can be placed blind, so only one side needs to be accessible;

- Can be installed quickly with the right tools, resulting in much lower labor costs;

- A strong and durable connection due to the large surface of the nut on the blind side;

- Blind rivet nuts can be applied after the coating process, which prevents contamination of the threads.

- Blind rivet nuts also enable modular assembly. At another stage of the assembly process, a bolt can be fitted in the blind rivet nut. Unlike with blind rivets, the screw connection can be disassembled (non-destructively) with a blind rivet nut. As a result, a blind rivet nut realizes a blind, flexible and strong connection.

Another advantage of blind riveting is the fact that no heat is released during the connection process, unlike welding. Partly because of this, any surface treatment of the workpiece, such as a lacquer or coating, is not damaged during the connection.

In addition, the multitude of mounting tools ensures that the blind rivet nuts can be installed pneumatically, electrically or manually. This variety of tools guarantees a controlled and fast way of fastening.

Wide range of blind rivet nuts

BIBUS has the right blind rivet nut available for every application. Examples of specific applications are, for example, when a blind rivet nut is not allowed to rotate quickly, when a larger bearing surface is required, or for placing a (blind rivet nut with external threaded end). A unique version is available for every application. The different versions are available in various sizes and materials,

Do you need help selecting the right blind rivet nut? The various steps in the selection process are explained in the article 'Selecting the right blind rivet or blind rivet nut'. In addition, our specialists are ready to provide you with tailor-made advice.

Blind Rivet Nut Tools

In addition to the wide range of blind rivet nuts, you will also find various blind rivet nut pliers in the BIBUS webshop. The right blind rivet nut tool ensures trouble-free mounting of any type of blind rivet nut. These blind rivet nut pliers are specially designed with a focus on ease of use and ergonomics. The range is divided into three categories: manual blind rivet nut tools, pneumatic blind rivet nut tools and battery blind rivet nut tools.

Order blind rivet nuts online

The range of blind rivet nuts can be ordered online via the webshop. Here you can easily order all available materials, versions and dimensions of blind rivet nuts. Do you need tailor-made advice or additional information? Please feel free to contact the specialists at BIBUS.