Blind rivets are used to connect thin plates, tubes, pipes and hinges, among other things. The connection mechanically connects two or more plates. Blind rivets can be used with both thin and thicker material. Blind rivets are still increasing in popularity as a fastening solution and for good reason. This article explains the operation and advantages of blind rivets.

How a blind rivet works

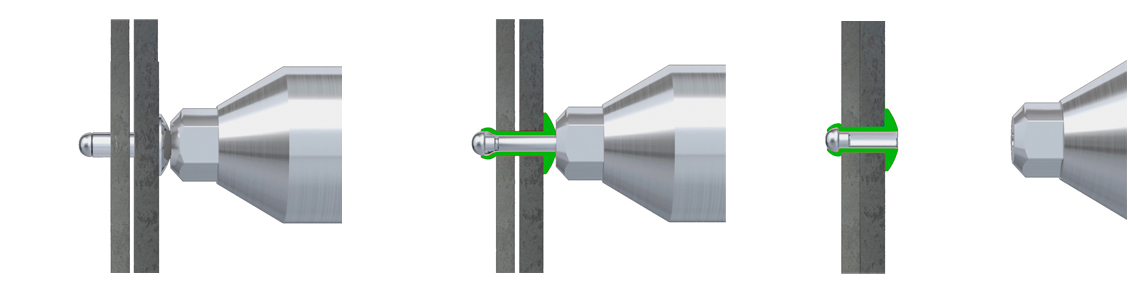

Blind rivets are also called pop rivets, rivets or rivets. A blind rivet consists of two components: the sleeve of the blind rivet and the draw pin. These parts of a blind rivet are visible in the image below. Both the sleeve and the pin are available in various materials, such as stainless steel (C1, A2 and A4), steel, aluminum, copper and bronze. In addition, the aluminum and steel rivets can be supplied in all RAL colors.

During blind riveting, the nail is positioned in a blind rivet tool. The sleeve of the nail is inserted through one side of a hole, after which the pin is pulled. The connection is created by the pulling motion, which causes the sleeve of the blind rivet to "roll up". The pin breaks after the connection is made (necking of the pin is the weakest link). Structural blind rivets leave a portion of the tie pin in the sleeve. This fills the entire opening of the sleeve, making this form of blind riveting a good alternative for welding, for example.

An example of blind riveting can be seen in the video below. Below the video you will find more information about blind rivet tools and the benefits of blind riveting.

Difference between blind rivets and blind rivet nuts

In the BIBUS range you will find both blind rivets and blind rivet nuts. A blind rivet consists of a combination of a blind rivet and a nut. In addition to a mechanical connection, this component also creates the possibility for a screw connection. The blind rivet nuts are also available in aluminum, steel and stainless steel.

Removing blind rivets

After installation, a blind rivet forms a strong and reliable connection. If you want to remove a blind rivet, you can simply drill it out. A metal drill with the diameter of the original hole diameter can be used. It is also possible to grind the head of the blind rivet with a grinder or to use a chisel to knock the head off the nail.

The CM07 blind rivet nut rubber can be used to create a non-permanent nut connection. When tension is released from the nut, the blind rivet nut returns to its original shape and can be removed.

Advantages of blind rivets

Blind rivets are often used to create a 'blind' connection, where only one side of the workpiece is accessible. As a result, a blind rivet can be used more flexibly to create a connection than, for example, clinching which is two-sided.

Blind riveting also makes modular assembly possible. The multitude of assembly tools means that the rivets can be installed pneumatically, electrically or manually. This variety of tools guarantees a controlled and fast way of fastening.

Another advantage of blind riveting is the fact that no heat is released during installation, unlike welding, for example. Partly because of this, any surface treatment of the workpiece, such as a coating, is not damaged during the connection. Because the blind rivets are placed after painting or coating, the production and logistics process is simplified.

BIBUS has all materials and versions of blind rivets and blind rivet nuts in its range. Think of blind rivets with a large clamping range, (semi-)structural rivets and water- and gas-tight blind rivets. The blind rivets and nuts can easily be ordered online in the webshop. Our specialists are happy to help you make the right choice.