New: MATRIX high speed valves

Why a MATRIX valve? MATRIX technology uses two highly innovative principles: the absence of internal friction during valve opening and closing (ZIF - Zero Internal Friction technology) and its modular architecture, which allows multiple valves to be mounted in one housing to achieve extreme performance and flexible configurations. This is what sets the MATRIX valves apart from 'traditional' solenoid valve technology! In addition, MATRIX uses Speed-Up technology, also known as peak & hold. The valve requires 100% response voltage from the control system during the opening phase and is then reduced to a holding voltage within a time period of <5 ms. This saves 90% of energy costs and reduces heat development at the same time! You will find the different series of these MATRIX valves on our website. For more information, click on the link below. If you need more information, please contact us at sales@bibus.nl or 0252-433733.

Click here for a complete overview of our high speed valves.

Lineair guides

Linear guides are used to allow movement along a straight line. They consist of a rail and a carriage that moves on the rail. This ensures very precise and smooth movements and is particularly suitable for automation processes! On our website you will find 4 series, namely the LSH, LSD, LRM and the LGC series. All models in this series are linear recirculating ball guides and can be moved manually, electrically or even pneumatically. Click on the link below to see the options per series.

Read more about the linear guides

Stainless steel T-handle

Stainless steel T-handle

New: In addition to the various handles, we now also have stainless steel T-handles in our range. These can be ordered with internal thread (AF56) or with threaded end (AF57), both are made of stainless steel 304, satin-finished and precision cast. For more information about these stainless steel T-handles, click on the link below.

Read more about the stainless steel T-handles

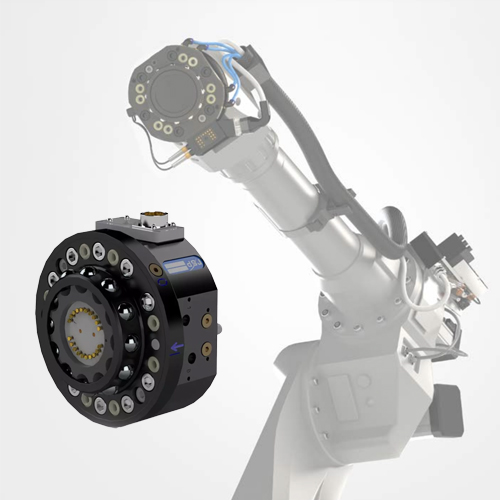

RSP tool changers

RSP tool changers are designed to maximize the flexibility and reliability of your robot fleet! For example, the robot can pick up a door, put the tool away and pick up another tool. This means that one robot can do the work of several robots, albeit less quickly, but more cost-efficiently! Click on the link below for more information or the link for a video.