The right gas spring for every application. That is the result of BIBUS' wide range of custom gas springs and quick ship gas springs. Our gas spring specialists are therefore always able to optimize the performance of your application with a Bansbach gas spring.

The extensive range of customer-specific gas springs consists, in addition to 'standard' gas springs, gas traction springs and lockable gas springs of gas springs with special properties. These specific characteristics ensure that gas springs can be installed in a special way or enable a deviating opening/closing of the gas spring. This article explains four gas springs with unique features from the BIBUS range.

End damping independent of the orientation of the gas spring

The video below shows a gas spring with end damping independent of the orientation of the gas spring.

This option uses a floating piston, which allows the gas spring to be positioned in any position while the damping remains functional. With a standard gas spring with standard piston, it is only possible to create damping if the piston rod is positioned vertically downward.

The floating piston ensures that nitrogen and oil remain separate. As a result, the piston always runs in oil, regardless of the installation of the gas spring. Here damping is possible at any position.

This type of gas spring is used in applications where horizontal movements are required. An example of this is closing a door or flap where there is no possibility to place the gas spring vertically. End damping independent of the orientation of the gas spring can be applied as an option to gas dampers, gas extension springs and gas compression springs.

Gas spring with dynamic damping and variable speed

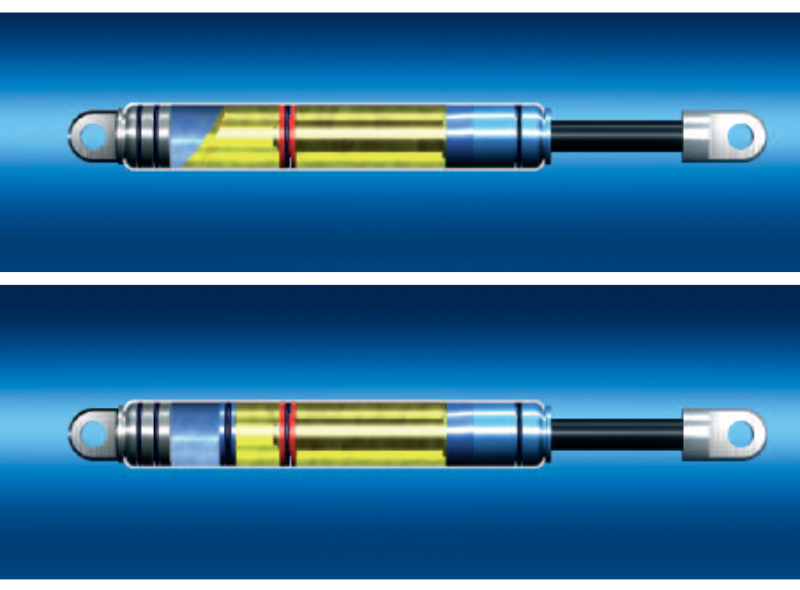

The following two gas springs in this article have dynamic damping. The groove in the cylinder wall of the gas spring (as seen below) allows you to control the amount of oil flowing from one chamber to the other. This can be applied on every position of the length of the cylinder.

The purpose of this groove is to provide different damping characteristics. The video below shows that the gas spring opens more slowly at the beginning of the stroke than at the end of the stroke.

The speed can be adjusted as desired. For example, it is possible to have a gas spring opening slowly at first, and then faster towards the end of the stroke, or vice versa. This can be completely determined according to the application during the design process. After manufacturing, it is not possible to change the speed again.

This type of gas spring is used when variable speed/damping is required. An example of such an application can be the phased opening of a valve. At the end of the stroke, the hatch is damped earlier than the standard damping can provide.

Gas spring with dynamic damping and integrated stop

This gas spring also has dynamic damping, which is made possible in part by a groove in the cylinder wall. The difference with the previous gas spring is that this groove does not run the entire length of the cylinder. At the point where the groove stops, the oil cannot flow any further.

Because the oil cannot flow further, the movement of the gas spring stops. It is possible to push the gas spring further manually, because there is nitrogen in the gas spring in addition to oil. This allows the stroke to extend completely. The video below shows an application of the gas spring with dynamic damping and integrated stop.

This type of gas spring is used, among other things, for ensuring safety. An example of this is when a valve is initially allowed up to a certain opening and not allowed to open further until it is safe. At the first part of the opening, for example, hot steam or gas can escape, after which the valve can be fully opened.

Gas spring with dynamic damping and blocking function

This gas spring combines dynamic damping with a stop function, by means of a lockable gas spring. Pressing the button unlocks the gas spring, allowing it to move. If the button is not pressed, the gas spring locks, making movement impossible. The video below shows the gas spring with dynamic damping and blocking function in action.

This gas spring is also used as a safety function. For example, when a valve may only be partially opened by hand. In this way a mechanic can, for example, service what is under the valve. When a button is pressed, the valve can be opened further for maintenance. The release can be set in both directions.

Gas springs with special characteristics

Gas springs with dynamic damping have several options. For example, the direction of damping can be selected inward, outward or both directions. The stroke of gas springs with dynamic damping ranges from 40 to 800 mm. The force ranges from 30 to 1,300 N.

BIBUS will work with you to put together the desired gas spring for your application. By combining the unique characteristics of Bansbach gas springs, more is possible. From ensuring safety to aesthetic considerations, BIBUS will help you further.

In consultation with BIBUS' gas spring specialists, the speed and amount of damping of the desired gas spring is determined for your application. Using a customer-specific sample, you can test the gas spring in your application. We are happy to help you with custom advice for the best solution without obligation.