How it works

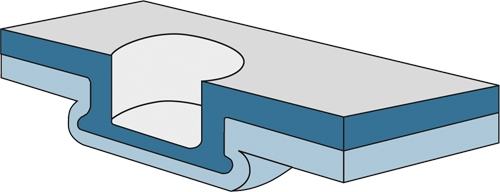

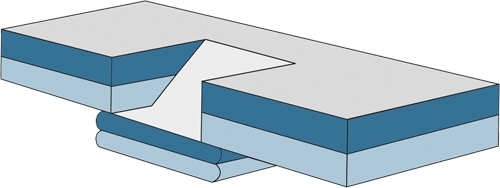

Clinching refers to the joining of sheet metal through localised cold forming processes of materials. This results in an interlocking connection between two or more layers of material. The SPOT CLINCH ® / RIVCLINCH ® bonding technique can be used to connect steel and stainless steel materials on the basis of a cost-effective and environmentally friendly process. Coated and painted metals can also be bonded without damaging the surface finish. The clinch for the end result can be either round or rectangular. This depends on the SPOT CLINCH ® selected tool.

How does clinching work?

The round clinch is gas-tight and provides better protection against high corrosion and fatigue resistance. The rectangular clinch is more suitable if multiple layers or harder materials (such as stainless steel) need to be connected.

In the clinching process of SPOT CLINCH® / RIVCLINCH®, the materials to be connected are first pressed into the mould with a die. Once the first layer of material rests on the anvil of the mould, the material starts to deform due to the pressure exerted by the punch. The movable mould sections are pushed out and the deformation of the sheet metal forms the knot-shaped connection.

The punch is then returned to its starting position by either the operator or a pneumatic timer that removes the force. The connected part can now be removed and the side parts of the mould are retracted by a spring.

Why Clinching

The SPOT CLINCH ® / RIVCLINCH ® bonding technique is simple, environmentally friendly, and cost-effective. Clinching has even more advantages, however:

- No smoke, no sparks, and very little noise

- Low energy consumption

- Environmentally friendly workplace

- No pre/post treatment required

- No thermal load on bundling zone

- No damage to workpiece surfaces

- Interim layers, film, or glue can be included in most cases

- Low maintenance costs

- No consumables

- Very good reproducibility

Mobile or stationary clinch machine

Mparts is the official distributor of Attexor clinch systems. We have both mobile and stationary clinch machines. Clinching techniques can be used in a wide variety of situations and can replace older bonding techniques.

Naturally, should you have any questions, please feel free to contact us. We are happy to advise you in choosing the right systems.