Linear guides, also known as linear rail sliders, ensure straight and level movement of loads and therefore play a crucial role in supporting linear motion.

This technology is widespread in various industrial sectors. Linear guides offer the ability to optimize machines, allowing products to move smoothly and safely through the production or packaging process.’

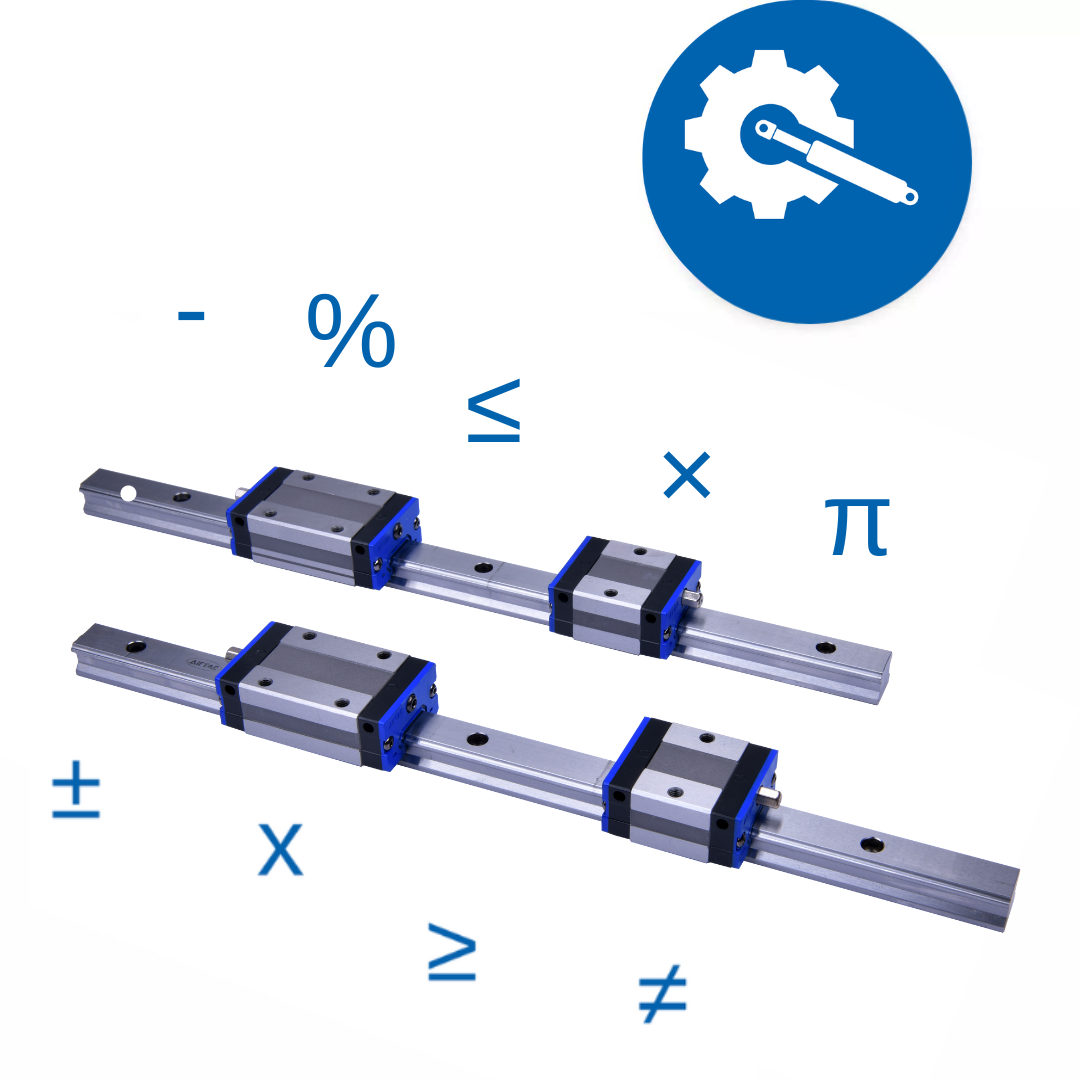

BIBUS supplies linear guides from manufacturer AirTAC. In this article, you can read more about configuring the desired linear guide.

Ball screw guide

There are several types of linear guides, the most common being the ball bearing guide. These guides provide support and guidance for linear motion in various machines.

A typical linear guide usually consists of two components: the sliding carriage and the rail. The sliding carriage is the moving element that slides smoothly along the rail. For the production of sliding carriages, Airtac uses high-quality materials.

The rails are available in different sizes and can be used for moving small masses to powerful systems that can effortlessly carry more than a ton. Thanks to the different types of linear guides, these rails can be tailored to the specific needs of different industrial applications.

Applications of linear guides in various industries

Linear guides are widely used in various industries, including robotic arms, CNC machines, packaging machines and conveyors. They provide reliable and precise operation with compact mounting in the machines.

Thus increasing productivity and reducing the risk of failure.

Thanks to their ability to accurately carry loads and operate reliably, linear guides are suitable for a variety of industries, including textiles, automation, packaging and woodworking.

Types of linear guideways with advantages

At BIBUS you will find a wide range of linear guides, which can be divided into different categories, such as cross roller guides, high rigidity guides and high precision guides. Some examples of the linear guides offered by BIBUS are:

- LSH-guides: These guides offer high rigidity and high load capacity, making them suitable for heavy-duty applications.

- LSD-guides: These guides have high rigidity, high load capacity and compact dimensions, making them ideal for applications where limited space is available.

- LRM-guides: These guides have a miniature design and are made of stainless steel. They are ideal for applications where limited space and high precision are required.

- LGC-guide: high rigidity, high precision. Made of stainless steel

If you have specific requirements or need more information, please contact one of our specialists. We will be happy to work with you to come up with a customized solution for your application.

How do you select the right linear Guide?

When selecting your linear guide, it is important to consider the ultimate application of the guide. You should be aware of the installation space, frequency of use and desired life of the guide. In addition, it is important to keep preload in mind.

The preload refers to the tension or force that is intentionally applied to the guide before it is put into service. Finally, preload eliminates the space between the guide rail and the block to improve accuracy of movement and rigidity. By selecting the right linear guide, you can visualize the installation options in the rail application, using our CAD configurator.

Step-by-step plan for configuring a linear guide:

- Determine the type of linear guide you need. Consult our blog for more information and details on the different types of guides.

- Choose the right series for your application let's take the LSH series as an example.

- Decide what type of linear guide you want. Do you want multiple blocks or just one block? In this example, we will choose the rail joint series.

- Select the model of linear guide. You have the choice between standard, LSH or LSD, depending on the requirements of your application.

- Select the desired rail width. BIBUS ranges from 15:15 mm to 35:34 mm. Select the width that best suits your needs.

- Determine the desired type of block for guidance.

- Select the desired length of the block. This can be short, regular or long, depending on the specific requirements of your application.

- Determine the number of blocks you need for guidance.

- Determine the desired length of the rail on which the blocks will be mounted.

- Determine the position of the mounting holes on the rail. At BIBUS, we offer the advantage that you can decide where the first position of the mounting holes will be, so that it fits your application perfectly.

- Choose the appropriate ordering code to indicate the desired width of the rail.

- After you complete these steps, you are ready to order the linear guide that best fits your specific application

Feel free to contact our specialists for advice on configuring your linear guide. We are always ready to help you make the right choices and ensure reliability.