The harsh environmental conditions and the presence of salt water demand high weather resistance on ship components to ensure reliable operation and long service life. Valves from müller co-ax must therefore meet various requirements.

Various quality and safety standards have been created, for example. These focus, for example, on quality requirements of components, the degree of corrosion resistance and reliability.

BIBUS enjoys working with the maritime sector. Engineers in the maritime sector like to work with stainless steel actuators for position adjustment of antenna brackets and masts or for access to the engine room of tenders, for example.

As a one-stop-shop supplier, BIBUS supplies a diversity of components to the maritime industry. Examples include stainless steel bracket handles, stainless steel hinges and valves. In this case study, we take a closer look at the role of coaxial valves in the maritime sector.

The maritime sector's requirements for valves

The requirements for process valves in maritime industries are related to the harsh conditions in which ships find themselves at sea. These conditions often prevent fast and regular maintenance. Because ships are always underway, it is also often difficult to obtain spare parts. In addition, due to limited space on board, the space available for maintenance is often limited. Especially in this type of application, valve reliability is very important.

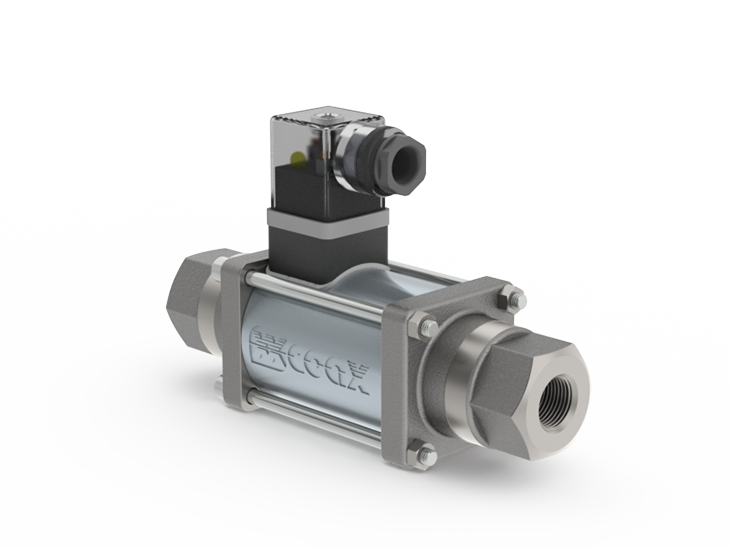

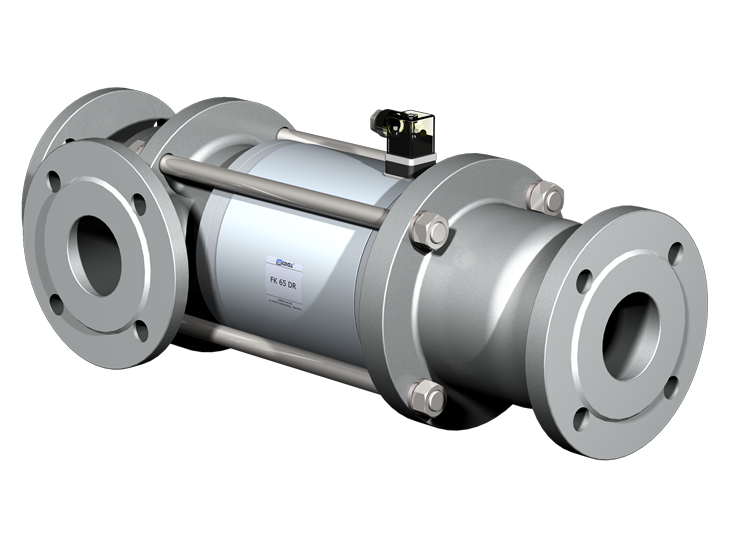

With the coaxial valves from muller coax, BIBUS offers a very reliable and efficient solution for the above requirements. The unique design of the coaxial valves ensures reliable handling of liquid, gaseous and contaminated media with minimal space requirements. Even when the valves are under high pressure. The robust design of these valves makes them particularly durable and low-maintenance.

The paragraphs below detail two applications of coaxial valves in the marine sector.

Application 1: coaxial valves for gas supply for ships

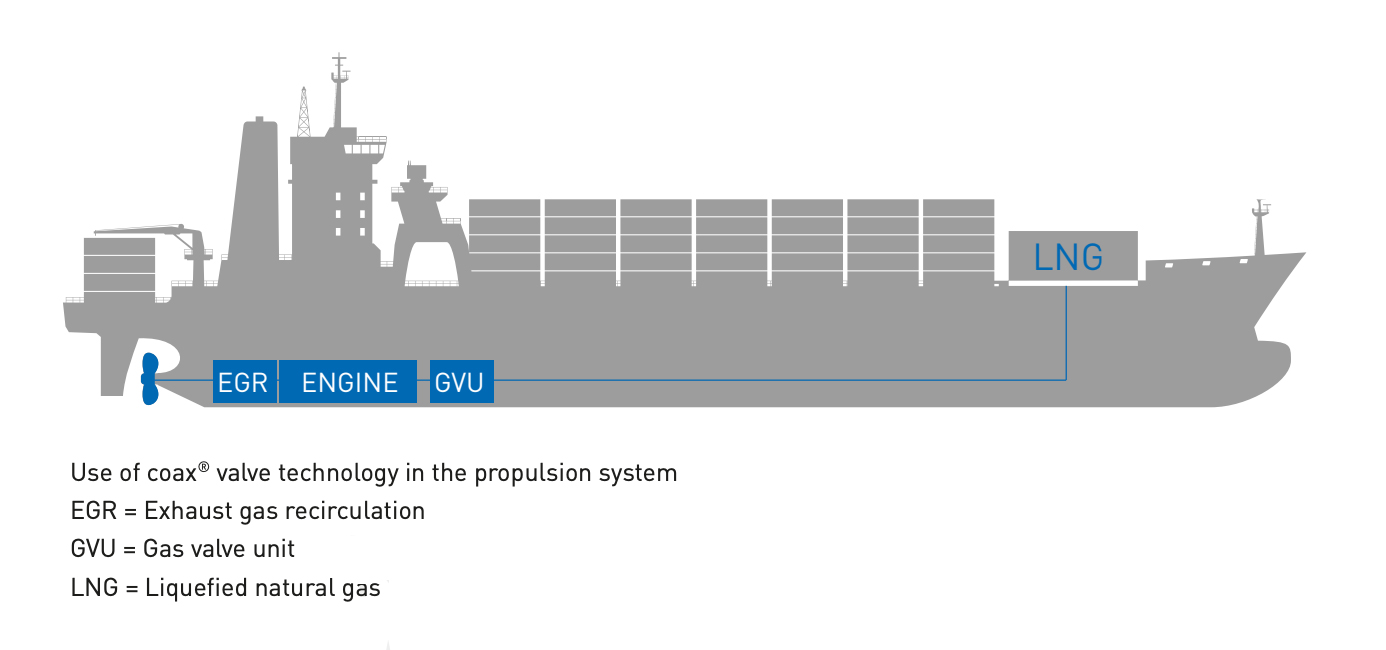

A common application of coaxial valves in the maritime sector can be found in controlling the supply of gas to the engine.Liquefied natural gas (LNG) is widely used as an environmentally friendly alternative to traditional, more polluting fuels.

Liquefied natural gas is stored on board ship at -162 °C, as it liquefies below this temperature.In its liquid state, the gas takes up less space, making it possible to store more energy in the same volume.

Shortly before use, when LNG enters the valve, it is reheated. The coaxial valve supplies the connected gas engine with the right amount of combustible gas for that specific pressure.The valve provides the ability to shut off the gas quickly and reliably in an emergency.

The coaxial valves from müller co-ax incorporate a space-saving 'double block and bleed' (DBB) design. This configuration features two valves. Here, one valve blocks the gas supply, while the other can be used to bleed. The DBB design improves valve reliability and helps prevent engine damage.

Application 2: coaxial valves for "dual fuel" engines

Not all marine engines operate on LNP. Dual fuel engines can operate on two types of fuel, gaseous and liquid. Because of this option, "dual fuel" engines offer a higher degree of flexibility than "standard" engines.

When powered by natural gas, the vessel benefits from environmental advantages. If the gas supply is interrupted, the engine can still operate on liquid fuel, this significantly improves reliability and the advantage of "dual fuel" technology is a reality.

Multiple coaxial valves in the engine compartment can be used for this application. Not only for supplying fuel, but also for starting the engine via compressed air. For safety reasons, the gas lines are flushed with an inert gas such as nitrogen. This is necessary to clear the pipes of fuel residues.

Coaxial valves from müller co-ax enable switching in a very fast and reproducible manner. To ensure smooth gas operation, reliability is essential.

Another factor in this application is the limited installation space around the engine. As a result, the valves must be as compact as possible.

Coaxial valves for the maritime industry

BIBUS works closely with the specialists at müller co-ax to provide tailor-made valve solutions for gas control systems. müller co-ax is able to guarantee the quality of these systems thanks to experience, laboratory tests and the high quality of the valves. Partly for this reason, the valves have various certificates and quality standards, including DIN EN ISO 9001, Pressure Equipment Directive 2014/68/EU, RoHS Directive 2011/65/EU, REACH, IECEx QAR and ATEX QAN.

Specialised housing and sealing materials are used in the design and manufacture of gas control systems, depending on the medium and environment. In addition to all standard valves, we are happy to think along with you in terms of specific solutions, which meet the requirements and wishes of your application.

Moreover, the available accessories and specialised connections make coax valves highly customisable. As a result, BIBUS can always offer the right solution for coaxial valves, even when exposed to back pressure.

These valves are used under and above water in the maritime sector, from cruise ships and yachts to LNG tankers and civilian submarines. For more information on the benefits of coaxial valves, please feel free to contact the specialists at BIBUS.