The components from our range are regularly used in the food industry because of their hygienic and qualitative properties. In order to meet all hygiene requirements, the machines and parts for this sector are often made of stainless steel.

Apollo Engineering

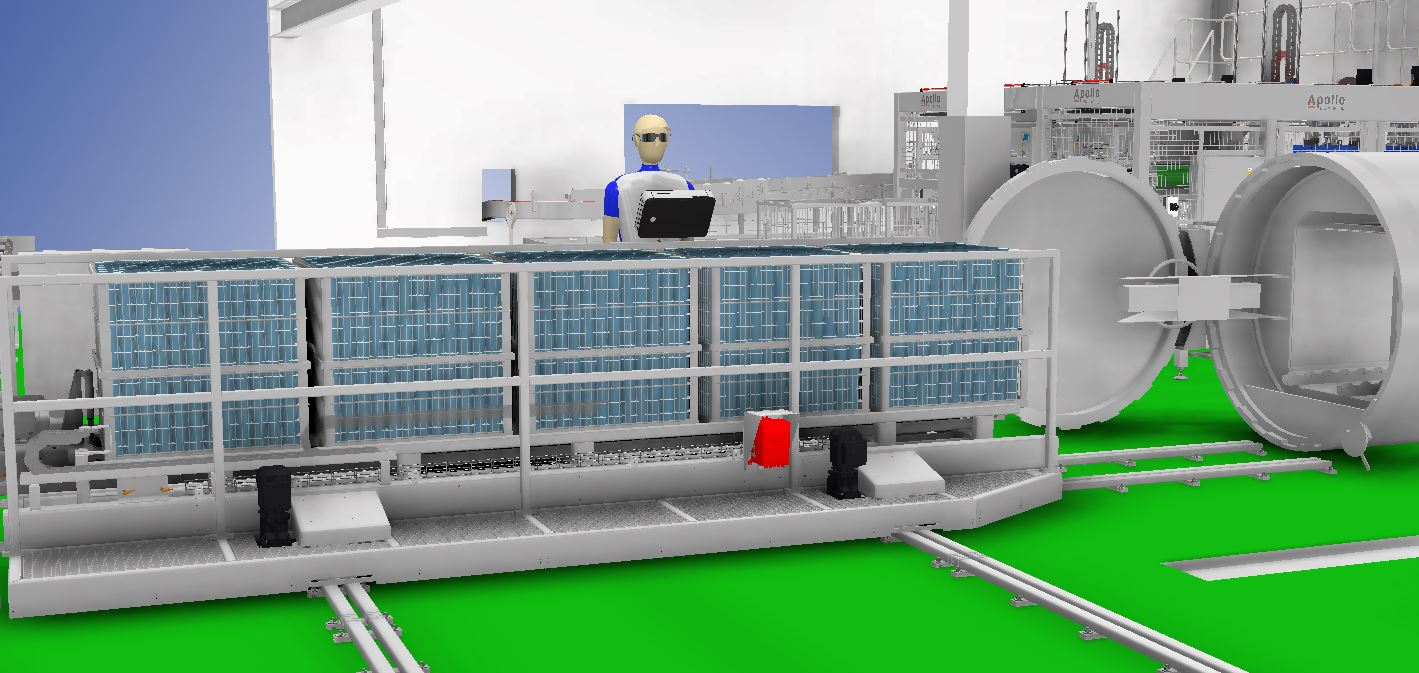

The current product application explains the use of a stainless steel actuator in the food industry. The Dutch engineering firm Apollo Engineering has applied the Bansbach actuator in an innovative way. This Dutch company designs and builds machines that connect to their customers' production lines. With its solid and creative solutions, the company is able to apply automation in production lines worldwide.

A good example of such an automation move is the project in question for a customer in Africa. In this production process, cans are filled with milk and then sterilized in a batch sterilizer.

The automated production process

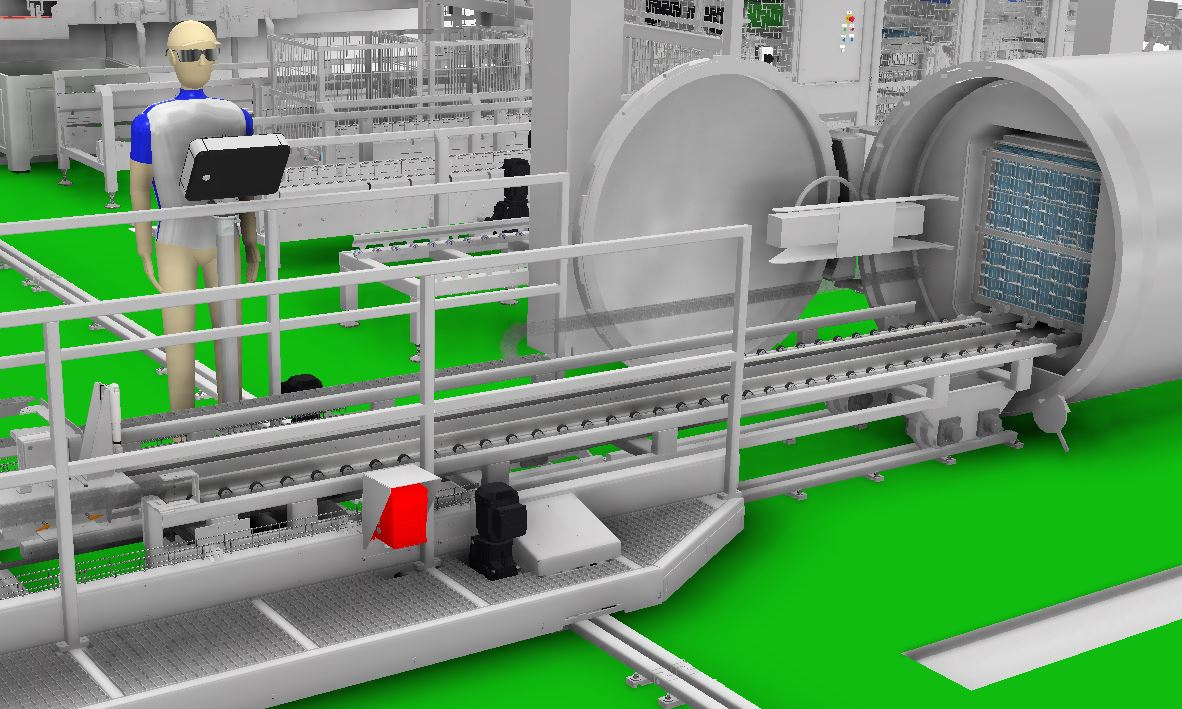

The production process starts when the baskets are filled with milk and transported to the basket loader. Here the cans are collected and picked up with a magnetic head to then load a waiting basket. In the end, five baskets are filled. The baskets are connected to each other by means of a pin connection.

The baskets are transported with a traverse carriage. The five baskets are then pushed from the traverse carriage into the autoclave to be sterilized. The image above shows the autoclave (right in the image above) and the traverse carriage (left in the image above).

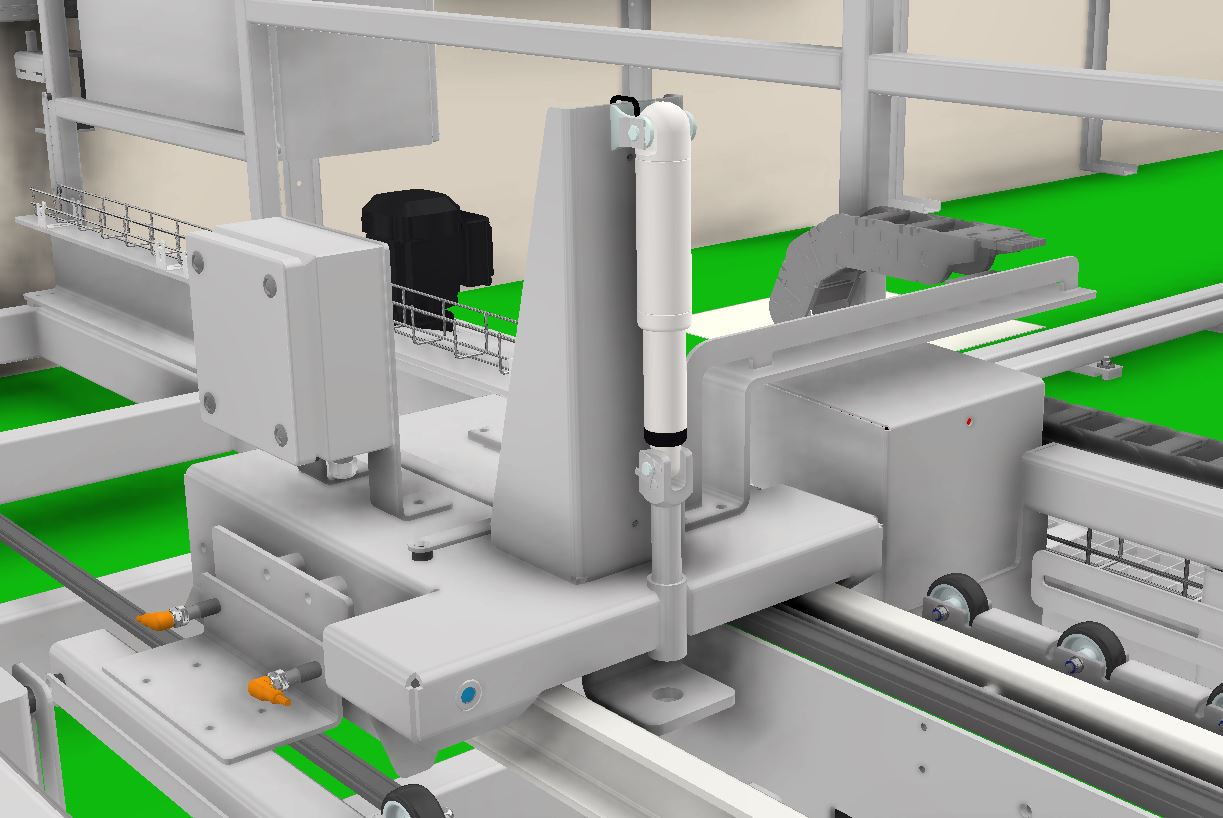

Because the autoclave does not have its own drive, the baskets in the current installation are manually removed from the autoclave. In order to automate this operation as well, a linear actuator from BIBUS was chosen.

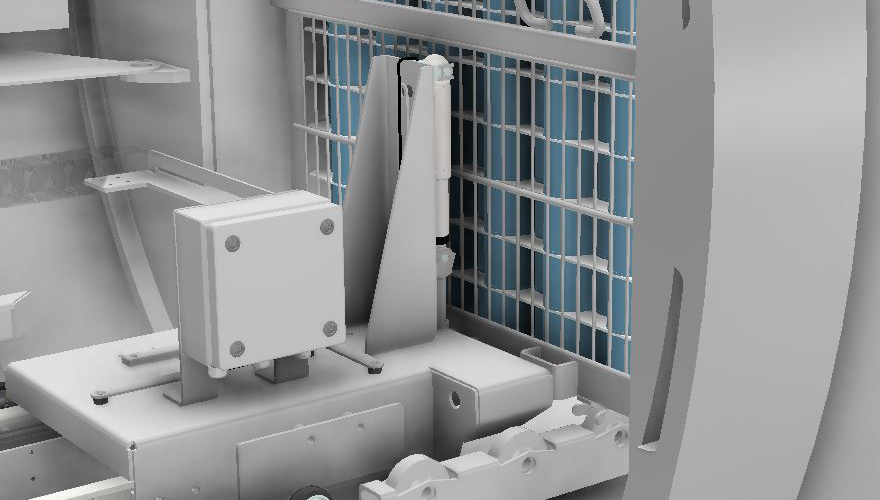

The actuator is used to position a pin downward. This functionality is shown in the image above. The pin secures the traverse carriage to the outer basket. As a result, the train of baskets can be removed from the autoclave by means of a pulling movement.

After the connection has been made by means of the actuator driven pin, the train with baskets can be placed on the traverse carriage. The traverse carriage then moves the train away from the autoclave. This operation is shown in the image below.

The choice for a linear actuator

There were several options for operating the pin, which is used to pull the train with baskets out of the autoclave. A traditional possibility was by means of an air cylinder. However, an air cylinder would also require compressed air, something that was not present in the set-up and is relatively expensive in the long run.

Would you like to read more about the choice between an electric linear actuator and a pneumatic cylinder? BIBUS engineers often think along with this decision and have summarized their findings on the issue of 'electric linear actuators as an alternative to pneumatic cylinders'.

The traverse carriage already has a 230V connection, so an electric linear actuator was chosen. As a result, no compressed air needs to be added to the process.

EasyE-35i actuator

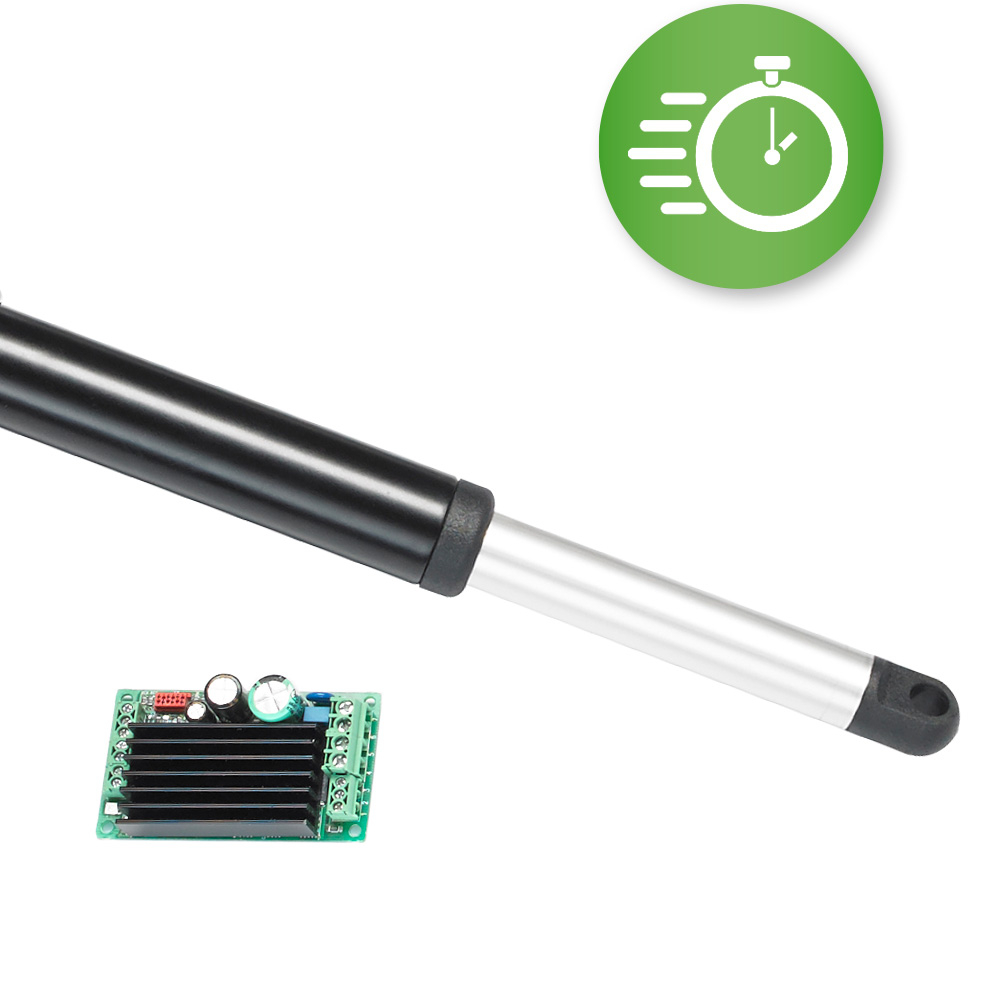

The stainless steel easyE-35i actuator used has an integrated control. The actuator has an adjustable start/stop speed, adjustable overcurrent protection, internal stroke limitation and internal overheating protection.

BIBUS actuators are produced by the German Bansbach. This company has been producing all types of gas springs for over 40 years. Bansbach is accredited according to ISO 9001:2008.

The full range of actuators with integrated control consists of 3 new 'in-line' models (easyE 35i, 50i and 60i). With the help of the built-in control, these actuators can be controlled individually or fully synchronously via the serial port RS485 connection to, for example, the 'plug and play' iConnect-Box by means of Modbus.

An advantage of the new concept is that the actuators have become just as compact as conventional actuators with a hall sensor. All EasyE-i models can be supplied with a cable length of 1-9 meters. Various end connectors are also available, such as eyes, clevises and spherical bearings. You can also choose a version in stainless steel 316, powder-coated black steel or in a RAL color of your choice.

Configure your own actuator

In the BIBUS range of actuators you will find quick ship actuators and customer-specific actuators. The quick ship variants can be delivered quickly to your home thanks to short delivery times. The customer-specific actuators offer a solution for specific solutions. You can easily configure this or have it put together by our specialists.